1. Introduction to SK800 Series Inverters

The working principle of frequency converters is based on power electronics technology, which controls the speed of AC motors by changing the power frequency. Its core function is to convert the fixed frequency and voltage AC electricity provided by the grid into AC electricity with variable frequency and variable voltage, so as to adjust the operating speed of the motor connected to the frequency converter. The following are the detailed steps of the frequency converter working principle:

Rectification stage: The frequency converter first converts the input AC into direct current (DC) through its internal rectifier (usually composed of diodes or thyristors). This process is called AC to DC conversion.

Intermediate DC link: The converted DC current flows into the intermediate DC link, which usually contains capacitors for smoothing DC fluctuations and providing a stable DC power supply.

Inversion stage: The DC power is then sent to the inverter unit. The inverter converts DC into AC with variable frequency by using insulated gate bipolar transistors (IGBTs) or similar switching elements. This process is realized through pulse width modulation (PWM) technology. By controlling the switching frequency and duty cycle of switching elements, AC output with different frequencies and amplitudes can be generated.

Output: The variable frequency AC obtained after inversion is sent to the motor, thus controlling the operating speed of the motor. By changing the output frequency, the speed of the motor can be controlled very accurately to meet the needs of different applications.

1.1 Application of Inverters in Industrial Manufacturing Industry

When we talk about the industrial manufacturing industry, the application of frequency converters is almost everywhere. They are an important part of modern industrial automation, helping factories achieve more efficient, more economical, and more reliable production processes.

Speed regulation and precise control:

- Frequency converters can precisely control the speed and torque of motors, which is crucial for many manufacturing processes. For example, in the textile industry, frequency converters can ensure that textile machinery runs at the appropriate speed to ensure product quality.

Improve energy efficiency:

- In the manufacturing industry, energy costs are an important consideration. Frequency converters reduce motor energy consumption by only providing the required power when needed, significantly reducing energy costs.

Reduce mechanical wear and maintenance:

- Frequency converters can smoothly start and stop motors, reducing mechanical wear and impact, thereby extending equipment life and reducing maintenance costs.

Process control and automation:

- In automated production lines, frequency converters can be integrated with sensors and control systems (such as PLCs) to achieve complex process control. For example, in food processing, frequency converters can adjust the speed of conveyor belts according to real-time data to match production needs.

Energy saving and environmental protection:

- Frequency converters help achieve energy saving and emission reduction goals. By optimizing motor energy use and reducing unnecessary power consumption, environmental impact is reduced.

Adapt to different process requirements:

- The flexibility of frequency converters makes them suitable for a variety of different processes and production needs, from heavy machinery to precision manufacturing.

In short, frequency converters are widely used in the industrial manufacturing industry. They improve production efficiency, save energy consumption, and enhance the flexibility of process control. With the continuous development of technology, the role of frequency converters in industrial manufacturing will become more and more important.

1.2 How to Choose the Right Inverter According to Load?

Choosing the right frequency converter needs to consider the following factors:

Load type: Different types of loads have different requirements for frequency converters. For example, constant torque loads (such as fans, centrifugal pumps) and constant power loads (such as compressors, conveyors) require different types of frequency converters to adapt to their specific working characteristics.

Load power: The rated power of the frequency converter should be greater than or equal to the rated power of the load to ensure that the frequency converter can operate normally and have a certain overload capacity.

Load inertia: The inertia of the load will affect the selection of the frequency converter. Large inertia loads require larger power frequency converters to ensure stable operation.

Starting characteristics: The starting characteristics of the load (such as starting torque, starting time) will affect the selection of the frequency converter, and it is necessary to ensure that the frequency converter has sufficient starting capacity.

Environmental conditions: Consider the environmental conditions where the load is located, such as temperature, humidity, etc., and select a frequency converter with appropriate environmental adaptability.

Control requirements: According to the control requirements for the load (such as speed accuracy, response time, etc.), select a frequency converter with corresponding control functions.

Cost considerations: After considering the above factors comprehensively, select the frequency converter with the highest cost performance, which can meet the load requirements without causing resource waste.

Considering the above factors comprehensively, you can select a frequency converter suitable for a specific load to ensure stable operation of the system and achieve optimal performance. It is best to consult a professional engineer or supplier when selecting a frequency converter to ensure that the selected frequency converter can best meet the system requirements.

2. Safety Precautions

Manual Warning Sign Definition

⚡Danger: Indicates that if the correct prompt is violated, it will be very likely to cause death or serious personal injury. ⚠️Warning: Indicates that if the correct prompt is violated, it may cause moderate or minor personal injury and equipment damage. ❗Note: Indicates that if the correct prompt is violated, it may lead to errors or unsafe use of the equipment.

Warning

⭕ If the frequency converter is damaged, flooded, or missing parts, it must not be installed or operated. Otherwise, it may cause equipment damage or personal injury.

⭕ When installing or moving, please hold the bottom of the product, do not only hold the shell, to prevent injury or damage to the frequency converter.

⭕ The frequency converter should be kept away from flammable and explosive objects, away from heat sources, and installed on metal and other flame-retardant materials.

⭕ When the frequency converter is installed in an electrical cabinet or other enclosed objects, a fan or other cooling device should be installed in the cabinet, and a vent should be set to ensure that the ambient temperature is below 40℃, otherwise the frequency converter may be damaged due to high ambient temperature.

⭕ Before wiring, confirm that the rated voltage and phase number of the frequency converter are consistent with the input power voltage and phase number, otherwise it may cause fire or personal injury.

⭕ AC input power cannot be connected to the output terminals U, V, W of the frequency converter, otherwise the frequency converter will be damaged and will not enjoy warranty service.

⭕ Do not perform withstand voltage test on the frequency converter, otherwise the frequency converter will be damaged.

⭕ The main circuit terminal wiring and control circuit wiring of the frequency converter should be routed separately or cross vertically, otherwise the control signal will be interfered.

⭕ The connection cable of the main circuit terminal should use wire lugs with insulating sleeves.

⭕ When the cable length between the frequency converter and the motor exceeds 50 meters, it is recommended to use an output reactor to protect the frequency converter and the motor.

⭕ Do not use circuit breakers to control the stop and start of the frequency converter, otherwise it may cause damage to the frequency converter.

⭕ Because the acceleration process time of the motor from low to high speed by the frequency converter is very short, please confirm that the motor and mechanical equipment are within the allowed use range before running, otherwise it may cause equipment damage.

⭕ The temperature of the radiator and brake resistor is high, please do not touch, otherwise it may cause burns.

⭕ The preset parameters of the frequency converter when leaving the factory can meet the operation requirements of most equipment. Unless necessary, please do not modify the parameters of the frequency converter arbitrarily. Even if some equipment has special requirements, only the necessary parameters can be modified. Otherwise, it may cause damage to the equipment.

Danger

⭕ Wiring must be completed by qualified professional electrical engineers, otherwise there may be electric shock or damage to the frequency converter.

⭕ Start wiring only when the power supply is in the disconnected state, otherwise it may cause electric shock or fire.

⭕ The grounding terminal ⏚ must be reliably grounded, otherwise there is a danger of the frequency converter shell being charged.

⭕ Do not touch the main circuit terminals, and the main circuit terminal wiring of the frequency converter should not contact the shell, otherwise it may cause electric shock.

⭕ The connection terminals (+), PB of the brake resistor, please do not connect terminals other than this, otherwise it may cause fire.

⭕ The frequency converter can be powered on only after the wiring is completed and the cover is added. It is strictly forbidden to remove the cover when it is powered on, which may cause electric shock.

⭕ When the fault automatic reset or automatic restart function after power failure is set for the frequency converter, safety protection measures should be taken for the equipment system in advance, otherwise it may cause personal injury.

⭕ The "run/stop" button may fail due to a certain function setting, and an independent emergency power-off switch can be installed in the frequency converter control system, otherwise it may cause personal injury.

⭕ After the frequency converter is powered on, even in the stop state, the terminals of the frequency converter are still live, and should not be touched, otherwise there is a danger of electric shock.

⭕ Do not touch the terminals of the frequency converter when it is powered on, otherwise it may cause electric shock.

⭕ Please designate qualified electrical engineers to carry out maintenance, inspection or replacement of parts.

⭕ After power off, wait at least 10 minutes or confirm that there is no residual voltage before performing maintenance and inspection, otherwise it may cause personal injury.

⭕ It is strictly forbidden to modify the frequency converter without permission, otherwise it may cause personal injury. Modified frequency converters will no longer enjoy warranty service.

Note

⭕ There are CMOS integrated circuits on the PCB, please do not touch with your hands, otherwise static electricity may damage the PCB.

3. Product Information

3.1 Technical Specification Table

| Item | Specification | ||

|---|---|---|---|

| Control characteristics | Control method | Sensorless vector control (SVC) | V/F control |

| Starting torque | 0.5Hz/150% | 0.5Hz/100% | |

| Speed regulation range | 1:100 | 1:50 | |

| Speed stabilization accuracy | ±0.5% | ±1% | |

| Carrier frequency | 0.5kHz~16kHz; can automatically adjust the carrier frequency according to load characteristics | ||

| Overload capacity | G type machine: 150% rated current 60s, 220% rated current 1sP type machine: 120% rated current 60s, 150% rated current 1s | ||

| Torque boost | 0.0% automatic torque boost; manual torque boost 0.1%~30% | ||

| Input and output | Input voltage range | 220V/380V; fluctuation range: ±15% | |

| Input frequency range | 50/60Hz; fluctuation range: ±5% | ||

| Output voltage range | 0~input voltage, error less than 5% | ||

| Output frequency range | SVC:0~320Hz; V/F:0-3200Hz | ||

| Operation control | Operation command channel | 3 channels: operation panel given, control terminal given, serial communication port given. Can be switched in a variety of ways. | |

| Frequency source | Digital given, panel potentiometer given, analog voltage given, analog current given, serial communication given, etc. Can be switched in a variety of ways. | ||

| Auxiliary frequency source | Multiple auxiliary frequency sources. Can perform frequency synthesis, frequency fine-tuning. | ||

| Input terminal | 7 digital input terminals2 analog input terminals | ||

| Output terminal | 2 open collector output terminals2 relay output terminals2 analog output terminals | ||

| Basic functions | DC braking function | Braking time: 0.0s~100.0s, braking action current value: 0.0%~100.0% | |

| V/F curve | 3 ways: linear, multi-point, square | ||

| Acceleration/deceleration curve | Linear or S-curve acceleration/deceleration mode; four groups of acceleration/deceleration time; acceleration/deceleration time range: 0.0~6500.0s | ||

| Simple PLC, multi-speed | Can realize up to 16-speed operation through built-in PLC or control terminal | ||

| Built-in PID | Can easily realize process control closed-loop control system | ||

| AVR function | When the grid voltage changes, it can automatically keep the output voltage constant | ||

| Overvoltage and overcurrent loss speed | Automatically limit the current and voltage during operation to prevent frequent overcurrent and overvoltage tripping | ||

| Fast current limiting function | Minimize overcurrent faults and improve system stability | ||

| Torque limitation and control | “Excavator” characteristic, automatically limit the torque during operation to prevent frequent overcurrent tripping | ||

| Power-on peripheral equipment safety self-inspection | Can realize power-on safety detection of peripheral equipment such as grounding, short circuit, etc. | ||

| Timing control function | Set time range 0h~65535h | ||

| Protection functions | Output phase loss protection, overcurrent protection, overvoltage protection, undervoltage protection, overheat protection, overload protection, power-on relay fault detection, etc. | ||

| Display and keyboard operation | LED display | 5-digit LED display | |

| Parameter lock function | Set parameter read-only control to prevent misoperation | ||

| MF.K key | Programmable key: command channel switching/forward and reverse operation/jog operation function selection/menu mode switching | ||

| Use environment | Use place | Indoor, not exposed to direct sunlight, no dust, corrosive gas, flammable gas, oil mist, water vapor, dripping water or salt, etc. | |

| Altitude | Below 1000m; when above 1000m, it is necessary to derate, and for every 100m increase, it is necessary to derate 1% | ||

| Ambient temperature | -10℃~40℃, when the temperature exceeds 40℃, it needs to be derated, and for every 1℃ increase in ambient temperature, it needs to be derated 1%, and the maximum ambient temperature is 50℃ | ||

| Humidity | ≤95%RH, avoid frost | ||

| Vibration | Vibration acceleration less than 0.6g | ||

| Storage temperature | -25℃~+60℃ |

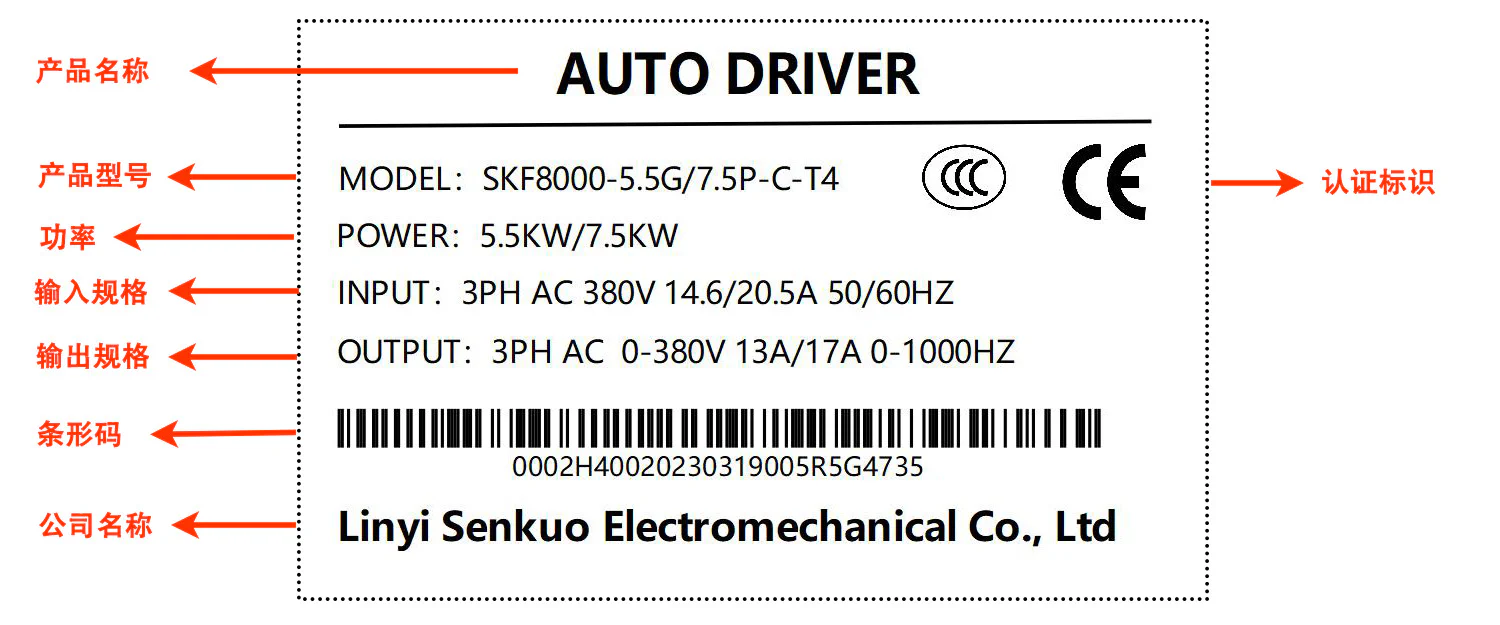

3.2 Product Nameplate

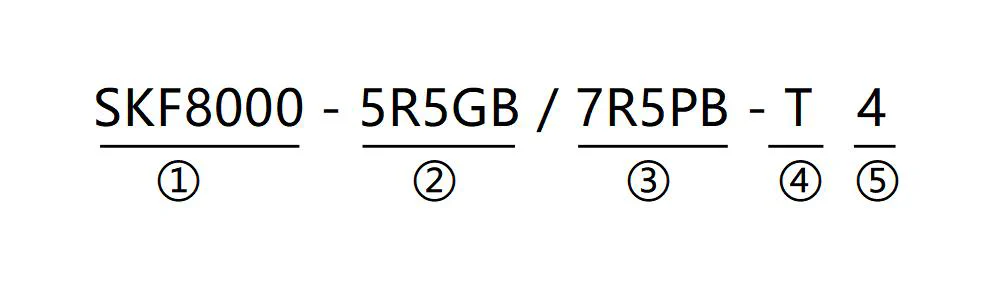

3.3 Model Description

| Field | Logo | Logo Description | Specific Content |

|---|---|---|---|

| Product series | ① | Product series | The general vector frequency converter series is 8000 |

| Rated power 1 | ② | G-type machine power range | 5R5-5.5KW, R is the decimal pointG-constant torque loadB-built-in brake unit |

| Rated power 2 | ③ | P-type machine power range | 7R5-7.5KW, R is the decimal pointP-variable torque loadB-built-in brake unit |

| Input power | ④ | Power phase number identification | S:single phase;T:three phase |

| Voltage level | ⑤ | Voltage level | 2:220VAC; 4: 380VAC |

3.4 Product Selection Specification Table

| Inverter model G/P | Rated power (kw) | Power capacity (KVA) | Input current(A) | Output current(A) | Adapted motor G/P(KW) | Adapted motor G/P(HP) |

|---|---|---|---|---|---|---|

| R75GB-S2 | 0.75 | 1.5 | 8.2 | 4.5 | 0.75 | 1 |

| 1R5GB-S2 | 1.5 | 3 | 14 | 7 | 1.5 | 2 |

| 2R2GB-S2 | 2.2 | 4 | 23 | 9.6 | 2.2 | 3 |

| R75GB-T4 | 0.75 | 1.5 | 3.4 | 2.1 | 0.75 | 1 |

| 1R5GB-T4 | 1.5 | 3 | 5.0 | 3.8 | 1.5 | 2 |

| 2R2GB-T4 | 2.2 | 4 | 5.8 | 5.1 | 2.2 | 3 |

| 004GB/5R5PB-T4 | 4/5.5 | 5.9/8.9 | 10.5/14.6 | 9/13 | 4/5.5 | 5.5/7.5 |

| 5R5GB/7R5PB-T4 | 5.5/7.5 | 8.9/11 | 14.6/20.5 | 13/17 | 5.5/7.5 | 7.5/10 |

| 7R5GB-T4 | 7.5 | 11 | 20.5 | 17 | 7.5 | 10 |

| 011GB/015PB-T4 | 11/15 | 17/21 | 26/35 | 25/32 | 11/15 | 15/20 |

| 015GB/18R5PB-T4 | 15/18.5 | 21/24 | 35/38.5 | 32/37 | 15/18.5 | 20/25 |

| 018R5GB/022PB-T4 | 18.5/22 | 24/30 | 38.5/46 | 37/45 | 18.5/22 | 25/30 |

| 022GB/030PB-T4 | 22/30 | 30/40 | 46.5/62 | 45/60 | 22/30 | 30/40 |

| 030G/037P-T4 | 30/37 | 40/57 | 62/76 | 60/75 | 30/37 | 40/50 |

| 037G/045P-T4 | 37/45 | 57/69 | 76/92 | 75/91 | 37/45 | 50/60 |

| 045G/055P-T4 | 45/55 | 69/85 | 92/113 | 91/110 | 45/55 | 60/70 |

| 055G/075P-T4 | 55/75 | 85/114 | 113/157 | 112/150 | 55/75 | 70/100 |

| 075G/093P-T4 | 75/93 | 114/134 | 157/180 | 150/170 | 75/93 | 100/125 |

| 093G/110P-T4 | 93/110 | 134/160 | 180/214 | 170/210 | 93/110 | 125/150 |

| 110G/132P-T4 | 110/132 | 160/192 | 214/256 | 210/253 | 110/132 | 150/180 |

| 132G/160P-T4 | 132/160 | 192/231 | 256/307 | 253/304 | 132/160 | 180/220 |

| 160G/185P-T4 | 160/185 | 231/245 | 307/345 | 304/340 | 160/185 | 220/250 |

| 185G/200P-T4 | 185/200 | 245/260 | 345/385 | 340/377 | 185/200 | 250/275 |

| 200G/220P-T4 | 200/220 | 260/280 | 385/430 | 377/426 | 200/220 | 275/300 |

| 220G/250P-T4 | 220/250 | 280/355 | 430/468 | 426/465 | 220/250 | 300/340 |

| 250G/280P-T4 | 250/280 | 355/396 | 468/525 | 465/520 | 250/280 | 340/380 |

| 280G/315P-T4 | 280/315 | 396/445 | 525/590 | 520/585 | 280/315 | 380/430 |

| 315G/355P-T4 | 315/355 | 445/500 | 590/665 | 585/650 | 315/355 | 430/480 |

| 355G/400P-T4 | 355/400 | 500/565 | 665/785 | 650/725 | 355/400 | 480/545 |

| 400G-T4 | 400 | 565 | 786 | 725 | 400 | 545 |

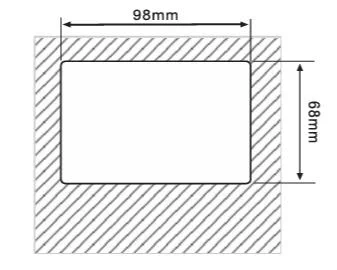

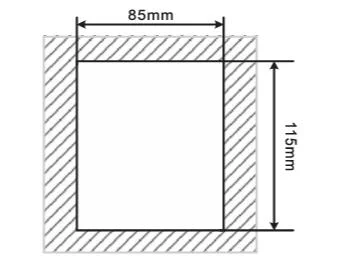

3.5 Keyboard Tray Dimension Drawing

| Inverter structure | C series tray opening size | H series tray opening size |

|---|---|---|

| Opening dimension drawing |  |  |

3.6 Daily Maintenance and Maintenance of Inverters

3.6.1 Daily Maintenance

Due to the influence of ambient temperature, humidity, dust and vibration, the internal components of the frequency converter will age, leading to potential failures of the frequency converter or reducing its service life. Therefore, it is necessary to carry out daily and regular maintenance and maintenance of the frequency converter.

Daily inspection items:

- Whether the sound of the motor changes abnormally during operation

- Whether the motor vibrates during operation

- Whether the installation environment of the frequency converter changes

- Whether the cooling fan of the frequency converter works normally

- Whether the frequency converter is overheated

Daily cleaning:

- The frequency converter should always be kept clean.

- Effectively remove dust on the surface of the frequency converter to prevent dust from entering the inside of the frequency converter. Especially metal dust.

- Effectively remove oil from the cooling fan of the frequency converter.

3.6.2 Regular Inspection

Please regularly check places that are difficult to check during operation.

Regular inspection items:

- Check the air duct and clean it regularly

- Check whether the screws are loose

- Check whether the frequency converter is corroded

- Check whether the wiring terminals have arc marks

- Main circuit insulation test Reminder: When measuring the insulation resistance with a megohmmeter (please use a DC 500V megohmmeter), the main circuit line should be disconnected from the frequency converter. Do not test the insulation of the control circuit with an insulation resistance meter. No high voltage test is required (completed at the factory).

3.6.3 Replacement of Vulnerable Parts of Inverters

The vulnerable parts of the frequency converter are mainly cooling fans and filtering electrolytic capacitors, and their service life is closely related to the use environment and maintenance conditions. The general service life is:

| Device name | Service life |

|---|---|

| Fan | 2~3 years |

| Electrolytic capacitor | 4~5 years |

Users can determine the replacement period according to the running time.

1)Cooling fan

Possible damage reasons: bearing wear, blade aging.

Judgment standard: whether there are cracks in the fan blades, whether there is abnormal vibration sound when starting.

2)Filter electrolytic capacitor

Possible damage reasons: poor input power quality, high ambient temperature, frequent load jumps, electrolyte aging.

Judgment standard: whether there is liquid leakage, whether the safety valve has protruded, measurement of electrostatic capacitance, measurement of insulation resistance.

3.6.4 Purchase of Inverters

After users purchase frequency converters, attention must be paid to the following points for temporary storage and long-term storage:

1)When storing, try to put it into our company’s packaging box according to the original packaging.

2)Long-term storage will lead to deterioration of electrolytic capacitors. It must be ensured that the power is turned on once within 2 years, and the power-on time is at least 5 hours. The input voltage must be slowly increased to the rated value with a voltage regulator.

3.7 Inverter Selection Guide

Frequency converters can provide three control methods: ordinary V/F, SVC, VC.

When selecting a frequency converter, you must first clarify the technical requirements of the system for variable frequency speed regulation, the application occasion of the frequency converter and the specific situation of the load characteristics, and comprehensively consider factors such as the adapted motor, output voltage, and rated output current, and then select a model that meets the requirements and determine the operation mode.

Basic principles:The rated load current of the motor cannot exceed the rated current of the frequency converter. Generally, select according to the motor capacity specified in the frequency converter manual, and pay attention to comparing the rated current of the motor and the frequency converter. The overload capacity of the frequency converter is only meaningful for the starting and braking process. Whenever there is a short-term overload during operation, it will cause a change in load speed. If the speed accuracy requirements are relatively high, please consider increasing one level.

Fan and pump type:It has low requirements for overload capacity. Because the load torque is proportional to the square of the speed, the load is lighter at low speed operation (except Roots blower). And because this type of load has no special requirements for speed accuracy, square torque V/F is selected.

Constant torque load:Most loads have constant torque characteristics, but generally have low requirements for speed accuracy and dynamic performance. For example, extruders, mixers, conveyors, factory transport trams, and the translation mechanism of cranes. When selecting a model, you can choose the multi-segment V/F operation mode.

The controlled object has certain dynamic and static index requirements:This type of load generally requires a harder mechanical characteristic at low speed to meet the dynamic and static index requirements of the production process for the control system. When selecting a model, you can choose the SVC control mode.

The controlled object has high dynamic and static index requirements:For occasions with high requirements for speed regulation accuracy and dynamic performance indicators and high-precision synchronous control, the VC control mode can be used. For example, elevators, papermaking, plastic film processing production lines.

3.8 Inverter Brake Component Selection Guide

3.8.1 Selection of Resistance Value

During braking, almost all the regenerative energy of the motor is consumed in the brake resistor.

According to the formula:U*U/R=Pb

●U in the formula—-Brake voltage for stable braking of the system

(Different systems are different, generally 700V for 380VAC system)

●Pb—-Brake power

3.8.2 Power Selection of Brake Resistance

Theoretically, the power of the brake resistance is consistent with the brake power, but considering derating to 70%

According to the formula:0.7Pr=PbD

●Pr—-Resistance power

●D—-Brake frequency (proportion of regeneration process in the entire working process)

Elevator—–20%-30%

Unwinding and winding—–20-30%

Centrifuge—–50%-60%

Accidental brake load-5%

Generally take 10%

3.8.3 Inverter Brake Component Selection Table

| Inverter power | Recommended power of brake resistance | Recommended resistance value of brake resistance | Brake unit | Remarks |

|---|---|---|---|---|

| 1.5KWT4 | 150w | ≥220Ω | Standard built-in | No special instructions |

| 2.2KWT4 | 250w | >200Ω | Standard built-in | No special instructions |

| 3.7KWT4 | 300W | ≥130Ω | Standard built-in | No special instructions |

| 5.5KWT4 | 400W | ≥90 Ω | Standard built-in | No special instructions |

| 7.5KWT4 | 500w | ≥65Ω | Standard built-in | No special instructions |

| 11KWT4 | 800w | ≥43Ω | Standard built-in | No special instructions |

| 15KWT4 | 1000w | ≥32Ω | Standard built-in | No special instructions |

| 18.5KWT4 | 1300w | ≥25Ω | Built-in optional | Add “B” after the inverter model |

| 22KWT4 | 1500w | ≥22Ω | Built-in optional | Add “B” after the inverter model |

| 30KWT4 | 2500w | ≥16Ω | Built-in optional | Add “B” after the inverter model |

| 37KWT4 | 3.7 kW | ≥16.0Ω | External | VFDBU-35-B |

| 45KWT4 | 4.5 kW | ≥16Ω | External | VFDBU-70-B |

| 55KWT4 | 5.5 kW | ≥8Ω | External | VFDBU-70-B |

| 75KWT4 | 7.5 kW | ≥8Ω | External | VFDBU-70-B×2 |

| 90KWT4 | 4.5 kW×2 | ≥8Ω×2 | External | VFDBU-70-B×2 |

| 110KWT4 | 5.5kW×2 | ≥8Ω×2 | External | VFDBU-70-B×2 |

| 132KWT4 | 6.5 kW×2 | ≥8Ω×2 | External | VFDBU-200-B |

| 160KWT4 | 16kW | ≥2.5Ω | External | VFDBU-200-B |

| 200KWT4 | 20 kW | ≥2.5Ω | External | VFDBU-200-B |

| 220KWT4 | 22 kW | ≥2.5Ω | External | VFDBU-200-B×2 |

| 250KWT4 | 12.5 kW×2 | ≥2.5Ω×2 | External | VFDBU-200-B×2 |

| 280KWT4 | 14kW×2 | ≥2.5Ω×2 | External | VFDBU-200-B×2 |

| 315KWT4 | 16kW×2 | ≥2.5Ω×2 | External | VFDBU-200-B×2 |

| 355KWT4 | 17kW×2 | ≥2.5Ω×2 | External | VFDBU-200-B×2 |

| 400KWT4 | 14kW×3 | ≥2.5Ω×3 | External | VFDBU-200-B×3 |

| 450KWT4 | 15kW×3 | ≥2.5Ω×3 | External | VFDBU-200-B×3 |

Note: ×2 means two brake units with their respective brake resistors are used in parallel, and ×3 has the same meaning as ×2.

Note

This selection table is a guide data, users can choose different resistance values and power according to the actual situation, (but the resistance value must not be less than the recommended value in the table, the power can be large.) The selection of brake resistance needs to be determined according to the power generated by the motor in the actual application system, which is related to system inertia, deceleration time, energy of potential energy load, etc., and needs to be selected by customers according to the actual situation. The greater the inertia of the system, the shorter the required deceleration time, and the more frequent the braking, the greater the power and smaller the resistance value of the brake resistance need to be selected.

4. Inverter Installation

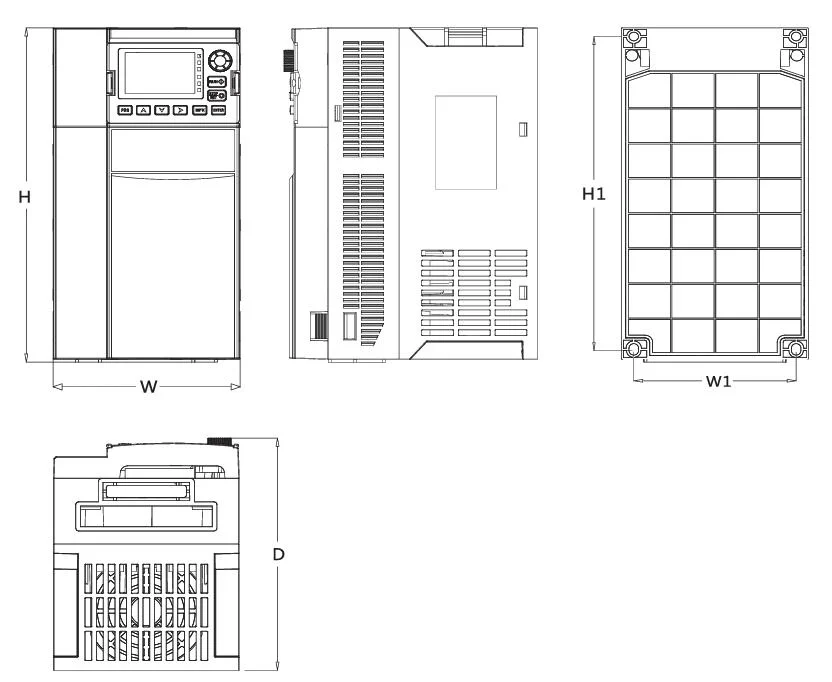

4.1 Overall Structure Dimension Drawing

| Model | H(mm) | W(mm) | D(mm) | H1(mm) | W1(mm) | Hole opening d(mm) |

|---|---|---|---|---|---|---|

| R75GB-S2 | 197.2 | 89.6 | 139 | 187 | 74 | 5 |

| 1R5GB-S2 | 197.2 | 89.6 | 139 | 187 | 74 | 5 |

| 2R2GB-S2 | 197.2 | 89.6 | 139 | 187 | 74 | 5 |

| R75GB-T4 | 197.2 | 89.6 | 139 | 187 | 74 | 5 |

| 1R5GB-T4 | 197.2 | 89.6 | 139 | 187 | 74 | 5 |

| 2R2GB-T4 | 197.2 | 89.6 | 139 | 187 | 74 | 5 |

| 004GB/5R5PB-T4 | 202 | 102 | 162 | 190.5 | 90 | 5 |

| 5R5GB/7R5PB-T4 | 202 | 102 | 162 | 190.5 | 90 | 5 |

| 7R5GB-T4 | 242.5 | 125 | 170 | 228 | 108.5 | 5 |

| 011GB/015PB-T4 | 242.5 | 125 | 170 | 228 | 108.5 | 5 |

| 015GB/18R5PB-T4 | 297 | 165 | 206 | 278 | 147 | 6 |

| 018R5GB/022PB-T4 | 297 | 165 | 206 | 278 | 147 | 6 |

| 022GB/030PB-T4 | 360 | 210 | 190 | 345 | 110 | 7 |

| 030G/037P-T4 | 435 | 230 | 230 | 418 | 150 | 7 |

| 037G/045P-T4 | 435 | 230 | 230 | 418 | 150 | 7 |

| 045G/055P-T4 | 510 | 260 | 255 | 200 | 493 | 7 |

| 055G/075P-T4 | 580 | 270 | 300 | 564 | 200 | 7 |

| 075G/093P-T4 | 580 | 270 | 300 | 564 | 200 | 7 |

| 093G/110P-T4 | 620 | 320 | 300 | 600 | 260 | 9 |

| 110G/132P-T4 | 620 | 320 | 300 | 600 | 260 | 9 |

| 132G/160P-T4 | 800 | 380 | 315 | 775 | 260 | 10 |

| 160G/185P-T4 | 800 | 380 | 315 | 775 | 260 | 10 |

| 185G/200P-T4 | 800 | 400 | 345 | 755 | 250 | 12 |

| 200G/220P-T4 | 900 | 450 | 350 | 875 | 350 | 12 |

| 220G/250P-T4 | 900 | 450 | 350 | 875 | 350 | 12 |

| 250G/280P-T4 | 900 | 450 | 350 | 875 | 350 | 12 |

| 280G/315P-T4 | 950 | 500 | 350 | 925 | 360 | 12 |

| 315G/355P-T4 | 1050 | 650 | 360 | 1029 | 500 | 12 |

| 355G/400P-T4 | 1050 | 650 | 360 | 1029 | 500 | 12 |

| 400G/450P-T4 | 1300 | 650 | 380 | 1265 | 500 | 12 |

| 450G/500P-T4 | 1300 | 650 | 380 | 1265 | 500 | 12 |

| 500G/560P-T4 | 1300 | 650 | 380 | 1265 | 500 | 12 |

| 560G/630P-T4 | 1500 | 800 | 400 | 1450 | 550 | 14 |

| 630G/720P-T4 | 1500 | 800 | 400 | 1450 | 550 | 14 |

| 720G/800P-T4 | 1500 | 800 | 400 | 1450 | 550 | 14 |

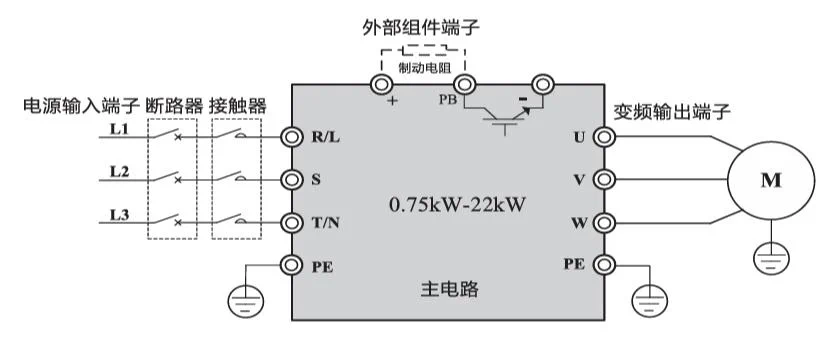

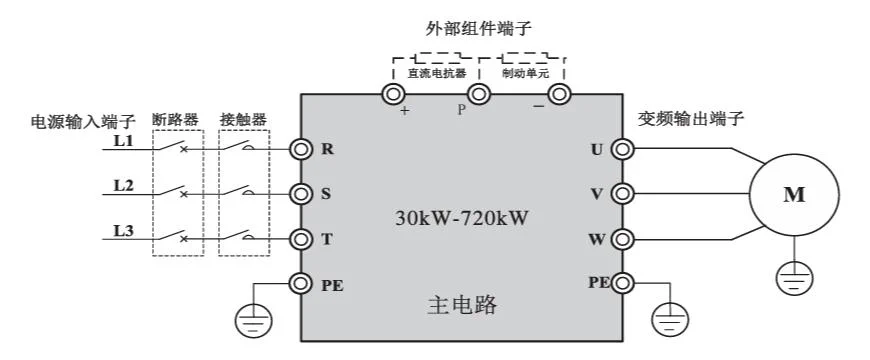

4.2 Main Circuit Terminal and Function

| Terminal mark | Name | Description |

|---|---|---|

| R、S、T | Three-phase power input terminal | Three-phase AC power input connection terminal |

| (+)、(-) | DC bus positive and negative terminals | Common DC bus input terminal (connection terminal of external brake unit above 30KW) |

| (+)、PB | Brake resistor connection terminal | 22KW and above brake resistor connection terminal |

| P、(+) | External reactor connection terminal | External DC reactor connection terminal |

| ⏚ | Grounding terminal | Connect to the earth |

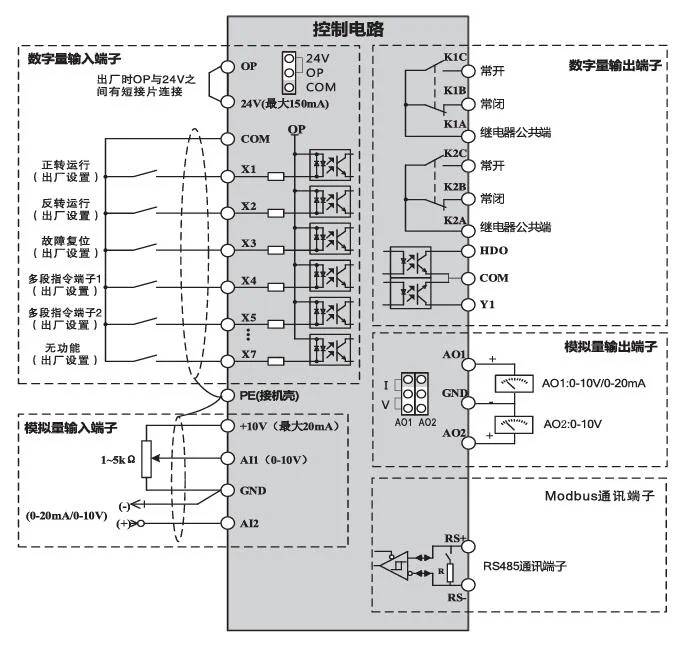

4.3 Control Circuit Terminal and Function

4.4 Control Terminal and Function

| Category | Terminal symbol | Terminal name | Function description |

|---|---|---|---|

| Power | +10V-GND | +10V power | Provide +10V power supply externally, maximum output current: 20mA, generally used as external potentiometer working power supply |

| Power | +24V-COM | +24V power | Provide +24V power supply externally, maximum output current: 150mA, generally used as working power supply for digital input and output terminals and external sensor power supply |

| Power | OP | External power input terminal | Select to connect with +24V or COM through the connection piece on the control board (default connected to +24V at the factory)When using external signal to drive DI1-DI6, OP needs to be connected to external power supply, and remove the short connection piece between OP-24V terminals here |

| Analog input | AI1-GND | Analog input terminal 1 | 1、Input range:DC0V~10V/0mA,selected by parameter P4-37 for voltage or current input.2、Input impedance:voltage input 22kΩ,current input 500Ω |

| Analog input | AI2-GND | Analog input terminal 2 | 1、Input range:DC0V~10V/0mA,selected by parameter P4-37 for voltage or current input.2、Input impedance:voltage input 22kΩ,current input 500Ω |

| Digital input | X1 、X2、X3、X4、X5、X6、X7 | Digital input 1、2、3、4、5、6、7 | 1、Optocoupler isolation2、Input impedance:4kΩVoltage range for level input:9V-30V |

| Analog output | AO1-GND | Analog output 1 | AO1, AO2 select voltage or current output by jumper on the control boardOutput voltage range:0V-10VOutput current range:0mA-20mADefault voltage output at factory |

| Analog output | AO2-GND(shared with Y1 for motors below 18.5KW, output selected by jumper) | Analog output 2 | AO1, AO2 select voltage or current output by jumper on the control boardOutput voltage range:0V-10VOutput current range:0mA-20mADefault voltage output at factory |

| Digital output | HD0 | High-speed pulse output open collector output | 1、Optocoupler isolation, bipolar open collector output.2、Output voltage range:0V-24VOutput current range:0mA-50mA(Note:Y1 function can be switched to analog output via jumper for motors below 18.5KW) |

| Digital output | Y1 | Digital output 1Analog voltage output 2 | 1、Optocoupler isolation, bipolar open collector output.2、Output voltage range:0V-24VOutput current range:0mA-50mA(Note:Y1 function can be switched to analog output via jumper for motors below 18.5KW) |

| Relay output | K1A-K1BK2A-K2B | Normally closed terminal | Contact driving capacity:AC 250V, 3A;DC 30V ,1A |

| Relay output | K1A-K1CK2A-K2C | Normally open terminal | Contact driving capacity:AC 250V, 3A;DC 30V ,1A |

| RS485 communication | RS+ | 485 communication terminal positive | RS485 differential signal positive terminal |

| RS485 communication | RS- | 485 communication terminal negative | RS485 differential signal negative terminal |

4.5 Mechanical Installation

4.5.1 Installation Environment:

Ambient temperature:The ambient temperature around the frequency converter has a great influence on its service life. The operating ambient temperature of the frequency converter is not allowed to exceed the allowable temperature range (-10℃~50℃).

Install the frequency converter on the surface of flame-retardant objects, with enough space around for heat dissipation. The frequency converter is easy to generate a lot of heat during work. And install it vertically on the mounting support with screws.

Please install it in a place not prone to vibration. The vibration should not be greater than 0.6G. Pay special attention to stay away from equipment such as punch presses.

Avoid installation in places exposed to direct sunlight, humidity, or water droplets.

Avoid installation in places with corrosive, flammable, or explosive gases in the air.

Avoid installation in places with oil, dust, or metal dust.

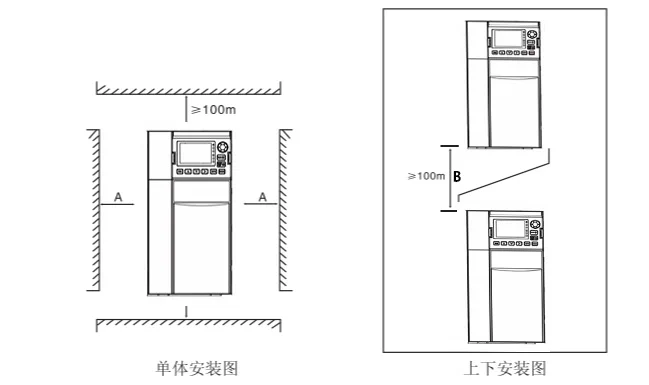

When installing individually: When the inverter power is not greater than 22kW, the A dimension may not be considered. When greater than 22kW, A should be greater than 50mm. When installing up and down: When installing the inverter up and down, please install the heat insulation deflector as shown in the figure.

| Inverter power | Installation dimension A | Installation dimension B |

|---|---|---|

| ≤15kW | No requirement | ≥100mm |

| 18.5kW—30kW | ≥50mm | ≥200mm |

| ≥37kW | ≥50mm | ≥300mm |

4.5.2 Mechanical Installation Notes

The key issue for mechanical installation is heat dissipation. So please note the following points:

Please install the frequency converter vertically to facilitate heat dissipation upward. But it cannot be inverted. If there are multiple frequency converters in the cabinet, it is best to install them side by side. In the case of upper and lower installation, please refer to the installation diagram to install the heat insulation deflector.

Follow the installation diagram to ensure the heat dissipation space of the frequency converter. But when arranging, please consider the heat dissipation of other devices in the cabinet.

The installation bracket must be flame retardant material.

For applications with metal dust, it is recommended to use the radiator external installation method. At this time, the fully sealed cabinet space should be as large as possible.

4.6 Inverter Peripheral Electrical Component Selection Guide

| Inverter power | Air switch(MCCB)A | Recommended contactorA | Recommended input side main circuit wire mm² | Recommended output side main circuit wire mm² | Recommended control circuit wire mm² |

|---|---|---|---|---|---|

| 0.4KWT2 | 16 | 10 | 2.5 | 2.5 | 1.0 |

| 0.7KWT2 | 16 | 10 | 2.5 | 2.5 | 1.0 |

| 1.5KWT2 | 20 | 16 | 4.0 | 2.5 | 1.0 |

| 2.2KWT2 | 32 | 20 | 6.0 | 4.0 | 1.0 |

| 0.7KWT4 | 10 | 10 | 2.5 | 2.5 | 1.0 |

| 1.5KWT4 | 16 | 10 | 2.5 | 2.5 | 1.0 |

| 2.2KWT4 | 16 | 10 | 2.5 | 2.5 | 1.0 |

| 3.7KWT4 | 25 | 16 | 4.0 | 4.0 | 1.0 |

| 5.5KWT4 | 32 | 25 | 4.0 | 4.0 | 1.0 |

| 7.5KWT4 | 40 | 32 | 4.0 | 4.0 | 1.0 |

| 11KWT4 | 63 | 40 | 4.0 | 4.0 | 1.0 |

| 15KWT4 | 63 | 40 | 6.0 | 6.0 | 1.0 |

| 18.5KWT4 | 100 | 63 | 6 | 6 | 1.5 |

| 22KWT4 | 100 | 63 | 10 | 10 | 1.5 |

| 30KWT4 | 125 | 100 | 16 | 10 | 1.5 |

| 37KWT4 | 160 | 100 | 16 | 16 | 1.5 |

| 45KWT4 | 200 | 125 | 25 | 25 | 1.5 |

| 55KWT4 | 200 | 125 | 35 | 25 | 1.5 |

| 75KWT4 | 250 | 160 | 50 | 35 | 1.5 |

| 90KWT4 | 250 | 160 | 70 | 35 | 1.5 |

| 110KWT4 | 350 | 350 | 120 | 120 | 1.5 |

| 132KWT4 | 400 | 400 | 150 | 150 | 1.5 |

| 160KWT4 | 500 | 400 | 185 | 185 | 1.5 |

| 200KWT4 | 600 | 600 | 150*2 | 150*2 | 1.5 |

| 220KWT4 | 600 | 600 | 150*2 | 150*2 | 1.5 |

| 250KWT4 | 800 | 600 | 185*2 | 185*2 | 1.5 |

| 280KWT4 | 800 | 800 | 185*2 | 185*2 | 1.5 |

| 315KWT4 | 800 | 800 | 150*3 | 150*3 | 1.5 |

| 355KWT4 | 800 | 800 | 150*4 | 150*4 | 1.5 |

| 400KWT4 | 1000 | 1000 | 150*4 | 150*4 | 1.5 |

Note

This selection table is a guide data, users can choose different sizes of electrical components according to the actual situation, but not less than the recommended values in the table.

5. Panel Display and Operation

5.1 Display Interface Introduction

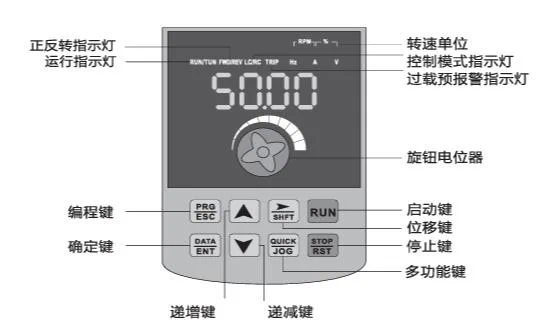

Using the operation panel, you can modify the functional parameters of the frequency converter, monitor the working status of the frequency converter, and start and stop the frequency converter, etc. Its appearance and functional areas are shown in the following figure:

C Series Inverter Operation Panel Indicator Lights and Button Functions

| Button symbol | Name | Function description |

|---|---|---|

| PRG | Programming key | Menu entry or exit, parameter modification |

| ENTER | Confirm key | Select parameter modification shift and display content |

| 🔼 | Increment key | Increment of data or function code |

| 🔽 | Decrement key | Decrement of data or function code |

| ▶️ | Shift key | According to function switch selection |

| RUN | Run key | Enter menu, confirm parameter setting |

| STOP/RESET | Stop/reset key | Run operation under keyboard operation mode |

| FUNC | Multi-function shortcut key | Jog |

| REV | Indicator light | Inverter reverse indicator, the light is on when in reverse operation state |

| FWD | Indicator light | Inverter forward indicator, the light is on when in forward operation state |

| ALM | Indicator light | Inverter fault indicator, the light is on when in fault state |

| Hz | Indicator light | Frequency unit |

| A | Indicator light | Current unit |

| V | Indicator light | Voltage unit |

H Series Inverter Operation Panel Indicator Lights and Button Functions

| Name | Function description |

|---|---|

| Unit indicator light | Hz:frequency unit;A:current unit;V:voltage unit;RMP(Hz+A):speed unit;%(A+V) :percentage |

| Status indicator light | RUN:on/running;off/stopped;FWD/REV:on/forward;off/reverse;flashing/forward and reverse switching;TUNE/TC:slow flash/tuning state;fast flash/communication state;slow flash about 1 time/second;fast flash about 2 times/secondLOCAL/REMOTE:on/terminal control;flashing/communication control;off/keyboard control. |

| PRG(Programming key) | First level menu entry or exit |

| ENTER(Confirm key) | Enter menu screen level by level, confirm parameter setting |

| 🔼(Increment key) | Increment of data or function code |

| 🔽(Decrement key) | Decrement of data or function code |

| ▶️ (Shift key) | In stop display interface and running display interface, you can cycle to select display parameters;when modifying parameters, you can select the modification bit of parameters. |

| RUN(Run key) | Used for run operation in keyboard operation mode. |

| STOP/RESET(Stop/reset key) | When in running state, press this key to stop running operation;when in fault alarm state, it can be used for reset operation, the characteristics of this key are restricted by function code F7.02. |

| MF.K(Multi-function shortcut key) | Switch selection according to F7.01 function. |

| Knob(Pulse potentiometer) | Can be used as frequency given source. When the frequency converter is set to use this knob as the frequency source, clockwise rotation increases the given, counterclockwise rotation decreases the given. |

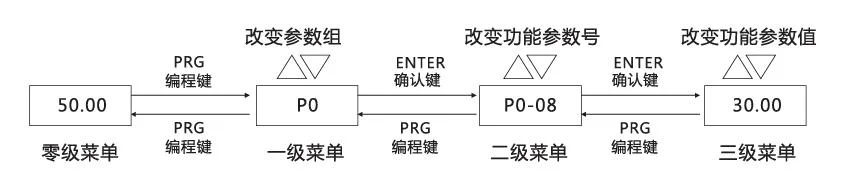

Inverter Function Code Viewing and Modification Method Description

The operation panel of the frequency converter adopts a three-level menu structure for parameter setting and other operations. The three-level menus are: functional parameter level (first-level menu) → function code (second-level menu) → function code setting value (third-level menu). The operation flow is shown in the following figure:

Note: In the third-level menu operation, you can press the PRG (programming) key or ENTER(confirm) key to return to the second-level menu. The difference between them is: pressing the ENTER(confirm) key will save the set parameters and return to the second-level menu, and automatically transfer to the next function code; while pressing the PRG(programming) key will directly return to the second-level menu without storing parameters, and return to the current function code.

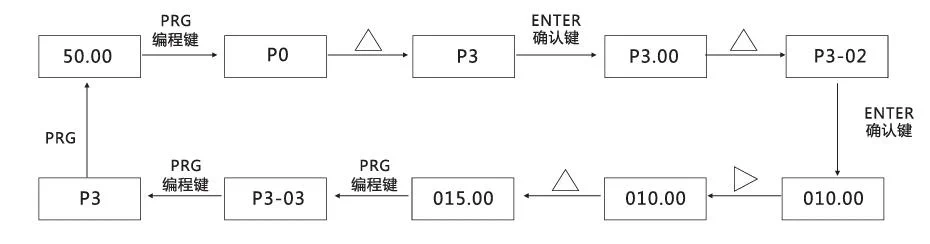

Example: Example of changing function code P3-02 from 10.00Hz to 15.00Hz. (Bold text indicates flashing bit)

In the third-level menu state, if the parameter has no flashing bit, it means that this function code cannot be modified. The possible reasons are:

- This function code is a non-modifiable parameter. Such as actual detection parameters, operation record parameters.

- This function code cannot be modified in running state, and needs to be modified after stopping.

5.2 Inverter Terminal Application Wiring Diagram

0.75~37KW Inverter Wiring Diagram

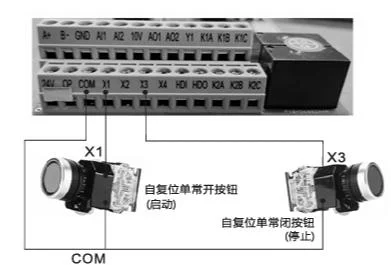

Description: Press the green button, the frequency converter starts; press the red stop button, the frequency converter stops;

Inverter parameter setting: P0-02=1;P4-02=3;P4-11=2

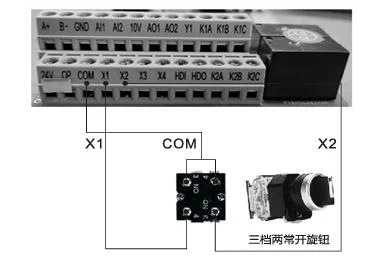

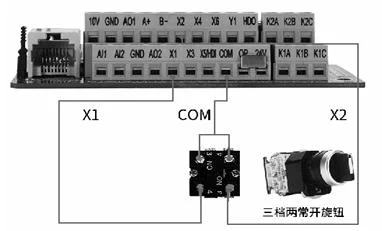

Description: Three-speed two normally open knob, turn to the left to rotate the motor forward, turn to the middle to stop the motor, turn to the right to rotate the motor reverse.

Inverter parameter setting: P0-02=1

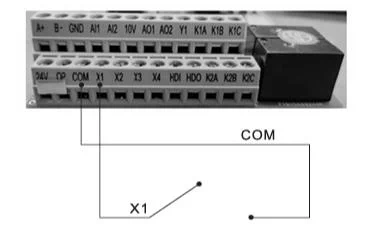

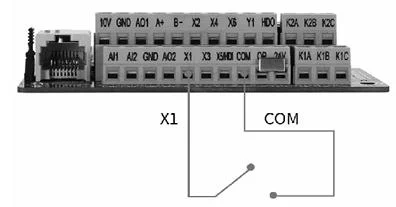

Description: When X1 terminal and COM terminal are connected, the frequency converter starts; when X1 terminal and COM terminal are disconnected, the frequency converter stops; start directly when power on, stop when power off, directly short COM and X1.

Inverter parameter setting: P0-02=1

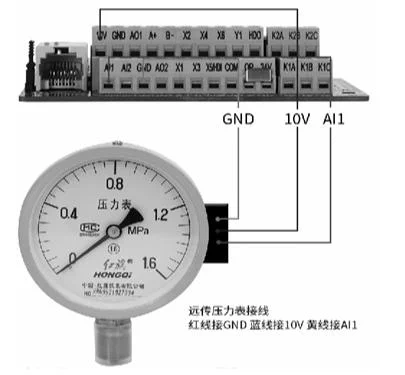

Description: As the core of the water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter setting: P0-29=00001, b0-00=pressure gauge range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the remote pressure gauge range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure gauge feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

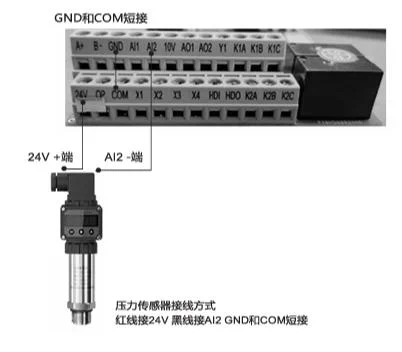

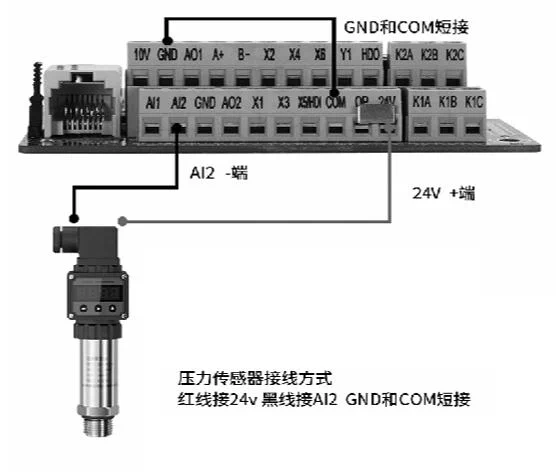

Description: As the core of the constant pressure water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter settings: P0-29=00001, b0-00=pressure transmitter range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the pressure transmitter range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure transmitter feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

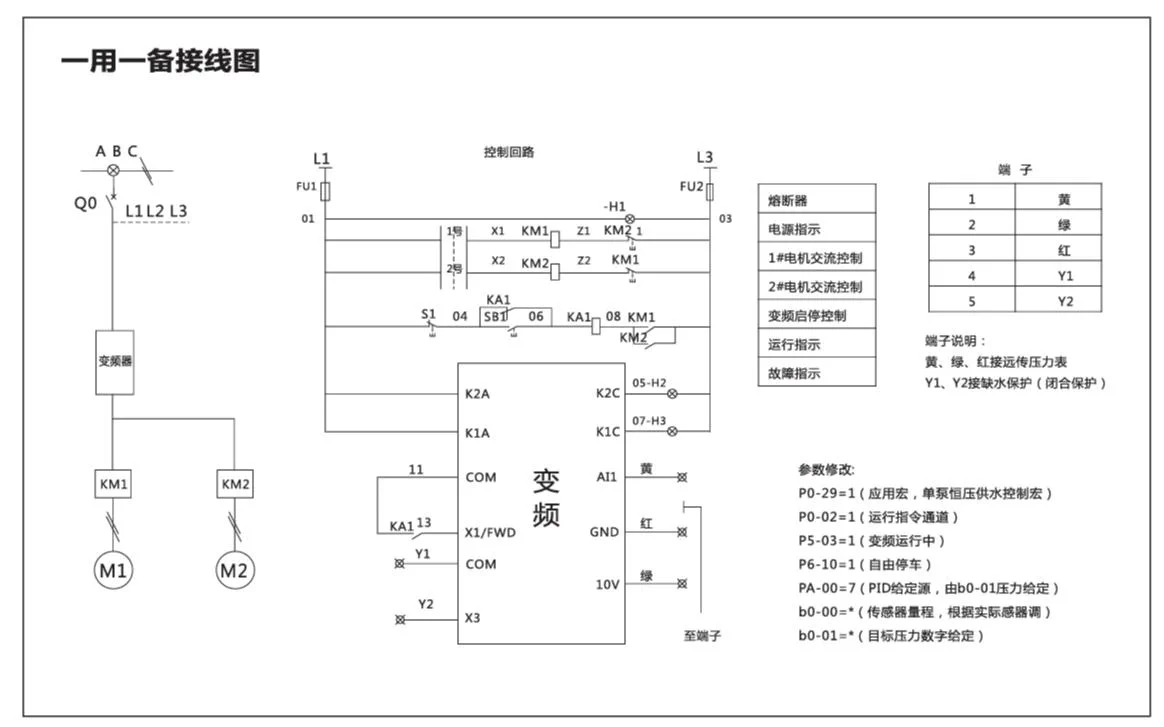

Description: As the core of the constant pressure water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter settings: P0-29=00001, b0-00=pressure transmitter range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the pressure transmitter range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure transmitter feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

45~720KW Inverter Wiring Diagram

Description: Press the green button, the frequency converter starts; press the red stop button, the frequency converter stops;

Inverter parameter settings: P0-02=1;P4-02=3;P4-11=2

Description: Press the green button, the frequency converter starts; press the red stop button, the frequency converter stops;

Inverter parameter settings: P0-02=1;P4-02=3;P4-11=2

Description: Three-speed two normally open knob, turn to the left to rotate the motor forward, turn to the middle to stop the motor, turn to the right to rotate the motor reverse.

Inverter parameter settings: P0-02=1

Description: Three-speed two normally open knob, turn to the left to rotate the motor forward, turn to the middle to stop the motor, turn to the right to rotate the motor reverse.

Inverter parameter settings: P0-02=1

Description: When X1 terminal and COM terminal are connected, the frequency converter starts; when X1 terminal and COM terminal are disconnected, the frequency converter stops; start directly when power on, stop when power off, directly short COM and X1.

Inverter parameter settings: P0-02=1

Description: When X1 terminal and COM terminal are connected, the frequency converter starts; when X1 terminal and COM terminal are disconnected, the frequency converter stops; start directly when power on, stop when power off, directly short COM and X1.

Inverter parameter settings: P0-02=1

Description: As the core of the constant pressure water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter settings: P0-29=00001, b0-00=pressure gauge range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the remote pressure gauge range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure gauge feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

Description: As the core of the constant pressure water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter settings: P0-29=00001, b0-00=pressure gauge range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the remote pressure gauge range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure gauge feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

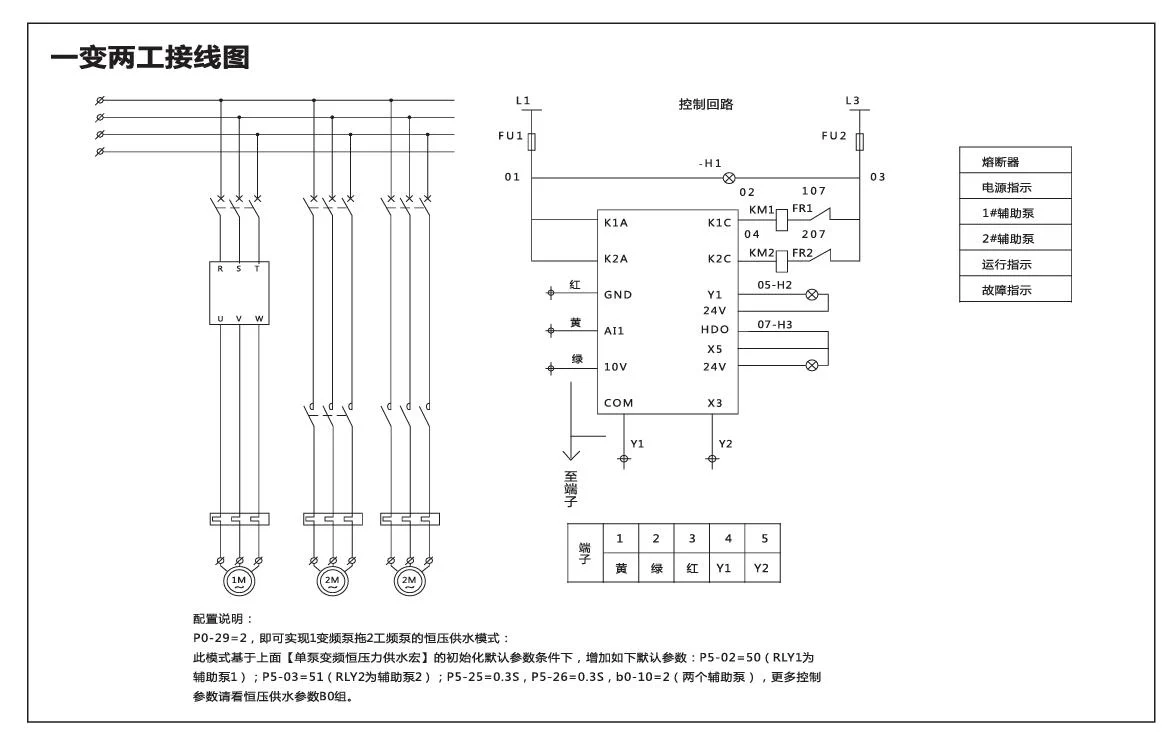

Description: As the core of the water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter settings: P0-29=00001, b0-00=pressure transmitter range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the pressure transmitter range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure transmitter feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

Description: As the core of the water supply system, the frequency converter can monitor water pressure changes in real time and intelligently adjust the speed of the water pump according to demand. When multiple users use water at the same time, the frequency converter will automatically increase the output power of the water pump to maintain stable water pressure; when using a smaller water flow, the frequency converter will reduce the output power of the water pump to avoid excessive water pressure.

Inverter parameter settings: P0-29=00001, b0-00=pressure transmitter range, b0-01=set pressure, b0-02=sleep pressure, b0-03=wake-up pressure;

Example: If the pressure transmitter range is 1MPA, b0-00=10, if the range is 1.6MPA, b0-00=16.

The upper row displays the set pressure, and the lower row displays the pressure transmitter feedback pressure. Change the set pressure by adjusting the panel increase 🔼/decrease 🔽 keys, and the display pressure unit is kg. The upper row can switch to display bus voltage, current, frequency, set pressure, and feedback pressure through the ▶️ key.

🌟Note 1: The above settings default to external terminal operation after P0-29=00001. If panel startup is required, set P0-02=0.

🌟Note 2: The settings of b0-02 and b0-03 are relative to the percentage of b0-01.

General Inverter Multi-speed Command Function Description

4 multi-speed command terminals can be combined into 16 states, and these 16 states correspond to 16 command setting values. The details are shown in the following table:

| K4 | K3 | K2 | K1 | Command setting | Corresponding parameter |

|---|---|---|---|---|---|

| OFF | OFF | OFF | OFF | Multi-stage designation 0 | PC-00 |

| OFF | OFF | OFF | ON | Multi-stage designation 1 | PC-01 |

| OFF | OFF | ON | OFF | Multi-stage designation 2 | PC-02 |

| OFF | OFF | ON | ON | Multi-stage designation 3 | PC-03 |

| OFF | ON | OFF | OFF | Multi-stage designation 4 | PC-04 |

| OFF | ON | OFF | ON | Multi-stage designation 5 | PC-05 |

| OFF | ON | OFF | ON | Multi-stage designation 6 | PC-06 |

| OFF | ON | ON | ON | Multi-stage designation 7 | PC-07 |

| ON | OFF | OFF | OFF | Multi-stage designation 8 | PC-08 |

| ON | OFF | OFF | ON | Multi-stage designation 9 | PC-09 |

| ON | OFF | ON | OFF | Multi-stage designation 10 | PC-10 |

| ON | OFF | ON | ON | Multi-stage designation 11 | PC-11 |

| ON | ON | OFF | OFF | Multi-stage designation 12 | PC-12 |

| ON | ON | OFF | ON | Multi-stage designation 13 | PC-13 |

| ON | ON | ON | OFF | Multi-stage designation 14 | PC-14 |

| ON | ON | ON | ON | Multi-stage designation 15 | PC-15 |

When the frequency source is selected as multi-speed, 100% of the function codes PC-00~PC-15 corresponds to PC-10 (maximum frequency)

6. Inverter Function Parameter Table

✅: Indicates that the setting value of this parameter can be changed when the frequency converter is in shutdown or running state; ✳️: Indicates that the setting value of this parameter cannot be changed when the frequency converter is in running state; ❎: Indicates that the value of this parameter is an actual detection record value and cannot be changed;

P0 Group: Basic Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P0-00 | G/P machine type | 1:G type2:P type | 1 | ✳️ | 61440 |

| P0-01 | Motor control mode | 0:Sensorless vector control2:V/F control | 2 | ✳️ | 61441 |

| P0-02 | Command source selection | 0:Panel command channel (LED off)1:Terminal command channel (LED on)2:Communication command channel (LED flashing) | 0 | ✅ | 61442 |

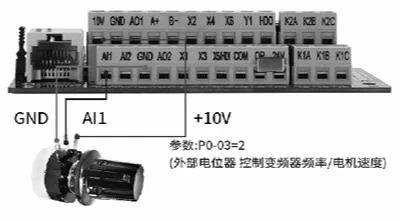

| P0-03 | Main frequency source X selection | 0:Digital setting (preset frequency P0-08, UP/DOWN can be modified, power-off does not remember)1:Digital setting (preset frequency P0-08, UP/DOWN can be modified, power-off remembers)2:AI13:AI24:AI3 keyboard potentiometer5:HDI pulse setting (X5)6:Multi-stage command7:Simple PLC8:PID9:Communication given | 4 | ✳️ | 61443 |

| P0-04 | Frequency source Y selection | Same as P0-03 (main frequency source X selection) | 0 | ✳️ | 61444 |

| P0-05 | Frequency source Y selection range when superimposed | 0:Relative to maximum frequency1:Relative to frequency source X | 0 | ✅ | 61445 |

| P0-06 | Frequency source Y range when superimposed | 0%~150% | 100% | ✅ | 61446 |

| P0-07 | Frequency source superposition mode selection | Units digit:Frequency source selection0:Main frequency source X1:Main and auxiliary operation (operation mode determined by tens digit)2:Main frequency source X and auxiliary frequency source Y switching3:Main frequency source X and main and auxiliary operation result switching4:Auxiliary frequency source Y and main and auxiliary operation result switchingTens digit:Main and auxiliary operation relationship of frequency source0:Main + auxiliary1:Main - auxiliary2:Maximum of both3:Minimum of both4:Main * auxiliary | 00 | ✅ | 61447 |

| P0-08 | Preset frequency | 0.00Hz~maximum frequency (P0-10) | 50Hz | ✅ | 61448 |

| P0-09 | Running direction | 0:Same direction1:Opposite direction | 0 | ✅ | 61449 |

| P0-10 | Maximum frequency | 50.00Hz | 50.00Hz50.0Hz | ✳️ | 61450 |

| P0-11 | Upper limit frequency source | 0:P0-12 setting1:AI12:AI23:AI3 external keyboard potentiometer4:HDI pulse setting5:Communication given | 0 | ✳️ | 61451 |

| P0-12 | Upper limit frequency | Lower limit frequency P0-14~maximum frequency P0-10 | 50.00Hz | ✅ | 61452 |

| P0-13 | Upper limit frequency offset | 0.00Hz~maximum frequency (P0-10) | 0.00Hz | ✅ | 61453 |

| P0-14 | Lower limit frequency | 0.00Hz~upper limit frequency (P0-12) | 0.00Hz | ✅ | 61454 |

| P0-15 | Carrier frequency | 0.5kHz~16.0kHz | Machine type determined | ✅ | 61455 |

| P0-16 | Carrier frequency adjustment with temperature | 0:No1:Yes | 0 | ✅ | 61456 |

| P0-17 | Acceleration time 1 | 0s | Machine type determined | ✅ | 61457 |

| P0-18 | Deceleration time 1 | Same as above | Machine type determined | ✅ | 61458 |

| P0-19 | Acceleration/deceleration time unit | 0:1 second1:0.1 second2:0.01 second | 1 | ✳️ | 61459 |

| P0-21 | Offset frequency of auxiliary frequency source when superimposed | 0.00Hz~maximum frequency (P0-10) | 0.00Hz | ✅ | 61461 |

| P0-22 | Frequency specified resolution | 1:0.1Hz2:0.01HzNote: Changing to 1 can achieve high frequency output | 2 | ✳️ | 61462 |

| P0-23 | Digital setting frequency shutdown memory | 0:Do not remember1:Remember | 0 | ✅ | 61463 |

| P0-24 | Reserved | - | 0 | ✅ | 61464 |

| P0-25 | Acceleration/deceleration time reference frequency | 0:Maximum frequency P0-101:Setting frequency | 0 | ✳️ | 61465 |

| P0-26 | Running frequency command UP/DOWN reference | 0:Running frequency1:Setting frequency | 1 | ✳️ | 61466 |

| P0-27 | Command source bundling frequency source | Units digit:Operation panel command binding frequency source selection0:No binding1:Digital setting frequency2:AI13:AI24:AI3 external keyboard potentiometer5:HDI pulse setting (X5)6:Multi-speed7:Simple PLC8:PID9:Communication givenTens digit:Terminal command binding frequency source selectionHundreds digit:Communication command binding frequency source selectionThousands digit:Automatic operation binding frequency source selection | 0000 | ✅ | 61467 |

| P0-28 | Reserved | ||||

| P0-29 | Application macro | Setting range:0~6553510000:Function code restore factory setting macro1:Frequency conversion single pump constant pressure water supply macro2:One drag three constant pressure water supply macro (1 variable 2 power frequency)3:One drag five constant pressure water supply macro (1 variable 4 power frequency)7:Fire inspection water supply macro11:CNC machine tool 100Hz macro 112:CNC machine tool 100Hz macro 221:Spindle engraving 400Hz macro 122:Spindle engraving 400Hz macro 2Note 1:Before selecting macro number, first execute P0-29 to restore factory value, then select macro number.Note 2:One drag multiple water supply see b0 parameter group | 0 | ✅ | 61469 |

P1 Group: Motor Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P1-00 | Motor type selection | 0:Ordinary asynchronous motor1:Frequency conversion asynchronous motor2:Permanent magnet synchronous motor (separate manual) | 0 | ✳️ | 61696 |

| P1-01 | Motor rated power | 0.1~1000KW | Machine type determined | ✳️ | 61697 |

| P1-02 | Motor rated voltage | 1~380V | Machine type determined | ✳️ | 61698 |

| P1-03 | Motor rated current | 0.01~100.00A | Machine type determined | ✳️ | 61699 |

| P1-04 | Motor rated frequency | 0.01Hz~maximum frequency | Machine type determined | ✳️ | 61700 |

| P1-05 | Motor rated speed | 1~65535rpm | Machine type determined | ✳️ | 61701 |

| P1-10 | Asynchronous motor no-load current | 0.01~P1-03 | Tuning parameter | ✳️ | 61706 |

| P1-37 | Tuning selection | 0:No operation1:Asynchronous machine static tuning2:Asynchronous machine complete tuning3:Static tuning 2 | 0 | ✳️ | 61733 |

P2 Group: Vector Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P2-00 | Speed loop proportional gain 1 | 1~100 | 30 | ✅ | 61952 |

| P2-01 | Speed loop integral time 1 | 0.01~10.00s | 0.50s | ✅ | 61953 |

| P2-02 | Switching frequency 1 | 0.00~P2-05 | 5.00Hz | ✅ | 61954 |

| P2-03 | Speed loop proportional gain 2 | 1~100 | 20 | ✅ | 61955 |

| P2-04 | Speed loop integral time 2 | 0.01~10.00s | 1.00s | ✅ | 61956 |

| P2-05 | Switching frequency 2 | P2-2~maximum frequency | 10.00Hz | ✅ | 61957 |

| P2-06 | Vector control slip gain | 50%~200% | 150% | ✅ | 61958 |

| P2-07 | Speed loop filtering time constant | 0.000~0.100s | 0.000s | ✅ | 61959 |

| P2-08 | Vector control overexcitation gain | 0~200 | 64 | ✅ | 61960 |

| P2-09 | Torque upper limit source in speed control mode | 0:Function code P2-10 setting1:AI12:AI23:Keyboard potentiometer4:PULSE pulse given5:Communication given6:MIN(AI1,AI2)7:MAX(AI1,AI2)1-7 options full scale corresponds to P2-10 | 0 | ✅ | 61961 |

| P2-10 | Torque upper limit digital setting in speed control mode | 0.0%~200.0% | 150.0% | ✅ | 61962 |

| P2-13 | Excitation regulation proportional gain | 0~60000 | 2000 | ✅ | 61965 |

| P2-14 | Excitation regulation integral gain | 0~60000 | 1300 | ✅ | 61966 |

| P2-15 | Torque regulation proportional gain | 0~60000 | 2000 | ✅ | 61967 |

| P2-16 | Torque regulation integral gain | 0~60000 | 1300 | ✅ | 61968 |

| P2-17 | Speed loop integral attribute | Units digit:Integral separation0:Invalid1:Valid | 0 | ✅ | 61969 |

P3 Group: V/F Control Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P3-00 | V/F curve setting | 1:G type2:P type | 1 | ✳️ | 62208 |

| P3-01 | Torque boost | 1:G type2:P type | 1 | ✅ | 62209 |

| P3-02 | Torque boost cutoff frequency | 1:G type2:P type | 1 | ✳️ | 62210 |

| P3-03 | Multi-point VF frequency point 1 | 1:G type2:P type | 1 | ✳️ | 62211 |

| P3-04 | Multi-point VF voltage point 1 | 1:G type2:P type | 1 | ✳️ | 62212 |

| P3-05 | Multi-point VF frequency point 2 | 1:G type2:P type | 1 | ✳️ | 62213 |

| P3-06 | Multi-point VF voltage point 2 | 1:G type2:P type | 1 | ✳️ | 62214 |

| P3-07 | Multi-point VF frequency point 3 | 1:G type2:P type | 1 | ✳️ | 62215 |

| P3-08 | Multi-point VF voltage point 3 | 1:G type2:P type | 1 | ✳️ | 62216 |

| P3-09 | VF slip compensation gain | 1:G type2:P type | 1 | ✅ | 62217 |

| P3-10 | VF overexcitation gain | 1:G type2:P type | 1 | ✅ | 62218 |

| P3-11 | VF oscillation suppression gain | 1:G type2:P type | 1 | ✅ | 62219 |

P4 Group: Input Terminal Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P4-00 | X1 terminal function selection | 0:No function1:Forward running (FWD)2:Reverse running (REV)3:Three-wire running control4:Forward jog (FJOG)5:Reverse jog (RJOG)6:Terminal UP7:Terminal DOWN8:Free parking9:Fault reset (RESET)10:Running pause11:External fault normally open input12:Multi-stage command terminal 113:Multi-stage command terminal 214:Multi-stage command terminal 315:Multi-stage command terminal 416:Acceleration/deceleration time selection terminal 117:Acceleration/deceleration time selection terminal 218:Frequency switching19:UP/DOWN setting clear (terminal/keyboard)20:Running command switching terminal 121:Acceleration/deceleration prohibition22:PID pause23:PLC state reset24:Swing frequency pause25:Counter input26:Counter reset27:Length counting input28:Length reset29:Torque control prohibition30:HDI pulse frequency input (X5)31:Reserved32:Immediate DC braking33:External fault normally closed input34:Frequency modification enable36:External parking terminal 137:Running command switching terminal 238:PID integral pause39:Frequency source X and preset frequency switching40:Frequency source Y and preset frequency switching43:PID parameter switching44:User-defined fault 145:User-defined fault 246:Speed control/torque control switching47:Emergency parking48:External parking terminal 249:Deceleration DC braking50:Current running time clear51:Two-wire and three-wire switching52:Prohibit reverse53:Single terminal UP/DOWN enable, frequency source switching (same function 18)54:Terminal activation UP, not activation DOWN | 01 | ✳️ | 62464 |

| P4-01 | X2 terminal function selection | Same as P4-00 | 02 | ✳️ | 62465 |

| P4-02 | X3 terminal function selection | Same as P4-00 | 04 | ✳️ | 62466 |

| P4-03 | X4 terminal function selection | Same as P4-00 | 09 | ✳️ | 62467 |

| P4-04 | X5 terminal function selection | Same as P4-00 | 12 | ✳️ | 62468 |

| P4-05 | X6 terminal function selection | Same as P4-00 | 00 | ✳️ | 62469 |

| P4-06 | X7 terminal function selection | Same as P4-00 | 00 | ✳️ | 62470 |

| P4-10 | X terminal filtering time | 0.000s~1.000s | 0.010s | ✅ | 62474 |

| P4-11 | Terminal command mode | 0:Two-wire 11:Two-wire 22:Three-wire 13:Three-wire 2 | 0 | ✳️ | 62475 |

| P4-12 | Terminal UP/DOWN change rate | 0.001Hz/s~65.535Hz/s | 1.00Hz/s | ✅ | 62476 |

| P4-13 | AI curve 1 minimum input | 0.00v~P4-15 | 0.00V | ✅ | 62477 |

| P4-14 | AI curve 1 minimum input corresponding setting | -100.0%~+100.0% | 0.0% | ✅ | 62478 |

| P4-15 | AI curve 1 maximum input | P4-13~+10.00V | 10.00V | ✅ | 62479 |

| P4-16 | AI curve 1 maximum input corresponding setting | -100.0%~+100.0% | 100.0% | ✅ | 62480 |

| P4-17 | AI filtering time | 0.00s~10.00s | 0.10s | ✅ | 62481 |

| P4-18 | AI curve 2 minimum input | 0.00V~P4-20 | 0.00V | ✅ | 62482 |

| P4-19 | AI curve 2 minimum input corresponding setting | -100.0%~+100.0% | 0.0% | ✅ | 62483 |

| P4-20 | AI curve 2 maximum input | P4-18~+10.00V | 10.00V | ✅ | 62484 |

| P4-21 | AI curve 2 maximum input corresponding setting | -100.O%~+100.0% | 100.0% | ✅ | 62485 |

| P4-22 | AI2 filtering time | 0.00s~10.00s | 0.10s | ✅ | 62486 |

| P4-23 | AI curve 3 minimum input | 0.00V~P4-25 | 0.00V | ✅ | 62487 |

| P4-24 | AI curve 3 minimum input corresponding setting | -100.O%~+100.0% | 0.0% | ✅ | 62488 |

| P4-25 | AI curve 3 maximum input | P4-23~+10.00V | 10.00V | ✅ | 62489 |

| P4-26 | AI curve 3 maximum input corresponding setting | -100.O%~+100.0% | 100.0% | ✅ | 62490 |

| P4-27 | AI3 filtering time | 0.00s~10.00s | 0.10s | ✅ | 62491 |

| P4-28 | HDI pulse minimum input | 0.00kHz~P4-30 | 0.00kHz | ✅ | 62492 |

| P4-29 | HDI pulse minimum input corresponding setting | -100.O%~+100.0% | 0.0% | ✅ | 62493 |

| P4-30 | HDI pulse maximum input | P4-28~50.00kHz | 50.00kHz | ✅ | 62494 |

| P4-31 | HDI pulse maximum input corresponding setting | -100.O%~+100.0% | 100.0% | ✅ | 62495 |

| P4-32 | HDI pulse filtering time | 0.00s~10.00s | 0.10s | ✅ | 62496 |

| P4-33 | AI curve selection | Units digit:AI1 curve selection1:Curve 1(2 points, P4-13 | 321 | ✅ | 62497 |

| P4-34 | AI lower than minimum input setting selection | Units digit:AI1 lower than minimum input setting selection0:Corresponding minimum input setting1:0.0%Tens digit:AI2 lower than minimum input setting selection, same as aboveHundreds digit:AI3 lower than minimum input setting selection, same as above | 000 | ✅ | 62498 |

| P4-35 | X terminal effective mode selection 1 | 0:High level effective1:Low level effectiveUnits digit:X1Tens digit:X2Hundreds digit:X3Thousands digit:X4Ten thousands digit:X5 | 000 | ✅ | 62499 |

| P4-37 | AI input voltage/current selection | Units digit:AI1Tens digit:AI20:Voltage input1:Current input | 000 | ✳️ | 62501 |

| P4-38 | X1 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62502 |

| P4-39 | X2 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62503 |

| P4-40 | X3 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62504 |

| P4-41 | X4 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62505 |

| P4-42 | X5 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62506 |

| P4-43 | X6 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62507 |

| P4-44 | X7 conduction delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62508 |

| P4-48 | X1 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62512 |

| P4-49 | X2 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62513 |

| P4-50 | X3 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62514 |

| P4-51 | X4 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62515 |

| P4-52 | X5 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62516 |

| P4-53 | X6 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62517 |

| P4-54 | X7 disconnection delay time | 0.0s~6553.5s | 0.0s | ✳️ | 62518 |

P5 Group: Output Terminal Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P5-00 | HDO terminal output mode selection | 0:High-speed pulse output(HDO)1:Terminal switch output(FMR) | 0 | ✅ | 62720 |

| P5-01 | HDO terminal switchoutput function selection(FMR) | 0:No output1:Inverter running2:Fault output(fault parking)3:Frequency level detection FDT1 output4:Frequency arrival5:Zero speed running(no output when parking)6:Motor overload pre-alarm7:Inverter overload pre-alarm8:Setting count value arrival9:Specified count value arrival11:PLC cycle completed12:Cumulative running time arrival13:Frequency limited14:Torque limited15:Running ready16:AI1>AI217:Upper limit frequency arrival18:Lower limit frequency arrival(related to running)19:Undervoltage state output20:Communication setting23:Zero speed running 2(output when parking)24:Cumulative power-on time arrival25:Frequency level detection FDT2 output26:Frequency 1 arrival output27:Frequency 2 arrival output28:Current 1 arrival output29:Current 2 arrival output30:Timing arrival output31:AI1 input overrun32:Load shedding33:Reverse running34:Zero current state35:Module temperature arrival36:Output current overrun37:Lower limit frequency arrival(also output when parking)38:Alarm output(continue running)40:Current running time arrival41:Fault output(fault parking and no undervoltage output)42:Frequency 1≤running frequency≤frequency 243:Frequency 1≥running frequency≥frequency 244:Frequency 1≤setting frequency≤frequency 245:Frequency 1≥setting frequency≥frequency 246:Linkage X1 terminal output47:Linkage X2 terminal output48:Linkage X3 terminal output49:Linkage X4 terminal output50:Auxiliary motor water pump 151:Auxiliary motor water pump 252:Auxiliary motor water pump 353:Auxiliary motor water pump 4 | 0 | ✅ | 62721 |

| P5-02 | Relay RY1 function selection(K1A-K1B-K1C) | Same as P5-01 | 2 | ✅ | 62722 |

| P5-03 | Relay RY2 function selection(K2A-K2B-K2C) | Same as P5-01 | 0 | ✅ | 62723 |

| P5-04 | Y1 output function selection | Same as P5-01 | 1 | ✅ | 62724 |

| P5-06 | HDO high-speed pulse output function selection | 0:Running frequency1:Setting frequency2:Output current3:Output torque4:Output power5:Output voltage6:HDI pulse input(100.0% corresponds to 100.0KHz)7:AI18:AI29:AI311:Count value12:Communication setting13:Motor speed14:Output current(100.0% corresponds to 1000.0A)15:Output voltage(100.0% corresponds to 1000.0V)16:Reserved17:Inverter output torque | 0 | ✅ | 62726 |

| P5-07 | AO1 output function selection | Same as P5-06 | 0 | ✅ | 62727 |

| P5-08 | AO2 output function selection | Same as P5-06 | 0 | ✅ | 62728 |

| P5-09 | HDO output maximum frequency | 0.01kHz~50.00kHz | 50.00kHz | ✅ | 62729 |

| P5-10 | AO1 zero offset coefficient | -100.00%~+100.00% | 0.0% | ✅ | 62730 |

| P5-11 | AO1 gain | -10.00~+10.00 | 1.00 | ✅ | 62731 |

| P5-12 | AO2 zero offset coefficient | -100.00%~+100.00% | 0.0% | ✅ | 62732 |

| P5-13 | AO2 gain | -10.00~+10.00 | 1.00 | ✅ | 62733 |

| P5-17 | FMR delay closing time | 0.0s~6553.5s | 0.0s | ✅ | 62737 |

| P5-18 | RY1 delay closing time | 0.0s~6553.5s | 0.0s | ✅ | 62738 |

| P5-19 | RY2 delay closing time | 0.0s~6553.5s | 0.0s | ✅ | 62739 |

| P5-20 | Y1 delay closing time | 0.0s~6553.5s | 0.0s | ✅ | 62740 |

| P5-21 | Reserved | - | - | - | 62741 |

| P5-22 | Y terminal output effective state selection | 0:Positive logic1:Negative logicUnits digit:HDO terminalTens digit:RY1Hundreds digit:RY2Thousands digit:Y1Ten thousands digit:Reserved | 00000 | ✅ | 62742 |

| P5-23 | AO current output selection | Units digit:AO1Tens digit:AO20:0 | 00 | ✅ | 62743 |

| P5-24 | FMR delay disconnection time | 0.0s~6553.5s | 0.0s | ✅ | 62744 |

| P5-25 | RY1 delay disconnection time | 0.0s~6553.5s | 0.0s | ✅ | 62745 |

| P5-26 | RY2 delay disconnection time | 0.0s~6553.5s | 0.0s | ✅ | 62746 |

| P5-27 | Y1 delay disconnection time | 0.0s~6553.5s | 0.0s | ✅ | 62747 |

P6 Group: Start-stop Control Parameters

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P6-00 | Start mode | 0:Direct start1:Speed tracking restart2:Pre-excitation start(AC asynchronous machine) | 0 | ✅ | 62976 |

| P6-01 | Speed tracking mode | 0:Start from parking frequency1:Start from zero speed2:Start from maximum frequency | 0 | ✳️ | 62977 |

| P6-02 | Speed tracking speed | 1~100 | 20 | ✅ | 62978 |

| P6-03 | Start frequency | 0~P0-08 | 0.00Hz | ✅ | 62979 |

| P6-04 | Start frequency holding time | 0.0s~100.0s | 0.0s | ✳️ | 62980 |

| P6-05 | Start DC braking current/pre-excitation current | 0%~100% | 0% | ✳️ | 62981 |

| P6-06 | Start DC braking time/pre-excitation time | 0.0s~100.0s | 0.0s | ✳️ | 62982 |

| P6-07 | Acceleration/deceleration mode | 0:Linear acceleration/deceleration1:S-curve acceleration/deceleration A2:S-curve acceleration/deceleration B | 0 | ✳️ | 62983 |

| P6-08 | S-curve start segment time ratio | 0.0%~(100.0%-P6-09) | 30.0% | ✳️ | 62984 |

| P6-09 | S-curve end segment time ratio | 0.0%~(100.0%-P6-08) | 30.0% | ✅ | 62985 |

| P6-10 | Parking mode | 0:Deceleration parking1:Free parking | 0 | ✅ | 62986 |

| P6-11 | Parking DC braking start frequency | 0.00Hz~maximum frequency | 0.00Hz | ✅ | 62987 |

| P6-12 | Parking DC braking waiting time | 0.0s~100.0s | 0.0s | ✅ | 62988 |

| P6-13 | Parking DC braking current | 0%~100% | 0% | ✅ | 62989 |

| P6-14 | Parking DC braking time | 0.0s~100.0s | 0.0s | ✅ | 62990 |

| P6-15 | Braking usage rate | 0%~100% | 100% | ✅ | 62991 |

P7 Group: Keyboard and Display

| Function code | Name | Setting range | Factory value | Attribute | DEC address |

|---|---|---|---|---|---|

| P7-01 | MF.K key function selection | 0:MF.K invalid1:Operation panel command channel and remote command channel(terminal command channel or communication command channel)switching2:Forward and reverse switching3:Forward jog4:Reverse jog | 2 | ✅ | 63233 |

| P7-02 | STOP/RESET key function | 0:Only in keyboard operation mode, STOP/RESET key parking function is effective1:In any case, STOP/RESET key parking function is effective | 1 | ✅ | 63234 |

| P7-03 | LED running display parameter 1 | 0000~FFFFBit00:Running frequency 1(Hz)Bit01:Setting frequency(Hz)Bit02:Bus voltage(V)Bit03:Output voltage(V)Bit04:Output current(A)Bit05:Output power(KW)Bit06:Output torque(%)Bit07:X input stateBit08:Y output stateBit09:AI1 voltage(V)Bit10:AI2 voltage(V)Bit11:AI3 panel potentiometer voltage(V)Bit12:Count valueBit13:ReservedBit14:Load speed displayBit15:PID setting(water supply macro display pressure value) | 001F | ✅ | 63235 |