Application and Development of Smart Power Distribution Systems in Industrial Fields

Senkuo Electromechanical

Electrical Technology ExpertFocused on R&D and application of industrial electrical automation, smart power distribution systems, and new energy technologies, with rich industrial project experience.

1. Introduction

With the arrival of the Industry 4.0 era, industrial enterprises have put forward higher requirements for the reliability, safety, and energy efficiency management of power supply. Traditional power distribution systems can no longer meet the needs of modern industrial production, and smart power distribution systems have emerged. This article will deeply explore the current application status, core technologies, advantages, and future development trends of smart power distribution systems in industrial fields. Smart power distribution systems integrate a variety of advanced electrical equipment, including High Voltage Switchgear, Low-Voltage Distribution Cabinets, and support Photovoltaic Power Generation and other new energy access.

2. Core Technologies of Smart Power Distribution Systems

2.1 IoT Technology

IoT technology is the foundation of smart power distribution systems, realizing interconnection and data sharing between devices by installing sensors and communication modules on power distribution equipment. It mainly includes:

- Wireless Sensor Networks (WSN)

- Industrial Ethernet

- 5G communication technology

- Low-power wide-area network technologies such as LoRaWAN

2.2 Big Data and Cloud Computing

The massive data generated by smart power distribution systems needs to be processed through big data analysis and cloud computing technologies to achieve:

- Real-time data collection and monitoring

- Fault prediction and diagnosis

- Energy efficiency analysis and optimization

- Trend prediction and decision support

2.3 Artificial Intelligence and Machine Learning

The applications of AI technology in smart power distribution systems mainly include:

- Anomaly detection and fault diagnosis

- Load forecasting and optimal scheduling

- Intelligent protection and self-healing control

- Predictive maintenance

3. Application Scenarios of Smart Power Distribution Systems in Industrial Fields

3.1 Industrial Enterprise Main Substation

In industrial enterprise main substations, smart power distribution systems can achieve:

- Intelligent monitoring and protection of high-voltage switchgear

- Condition monitoring and life management of transformers

- Intelligent control of reactive power compensation

- Harmonic monitoring and governance

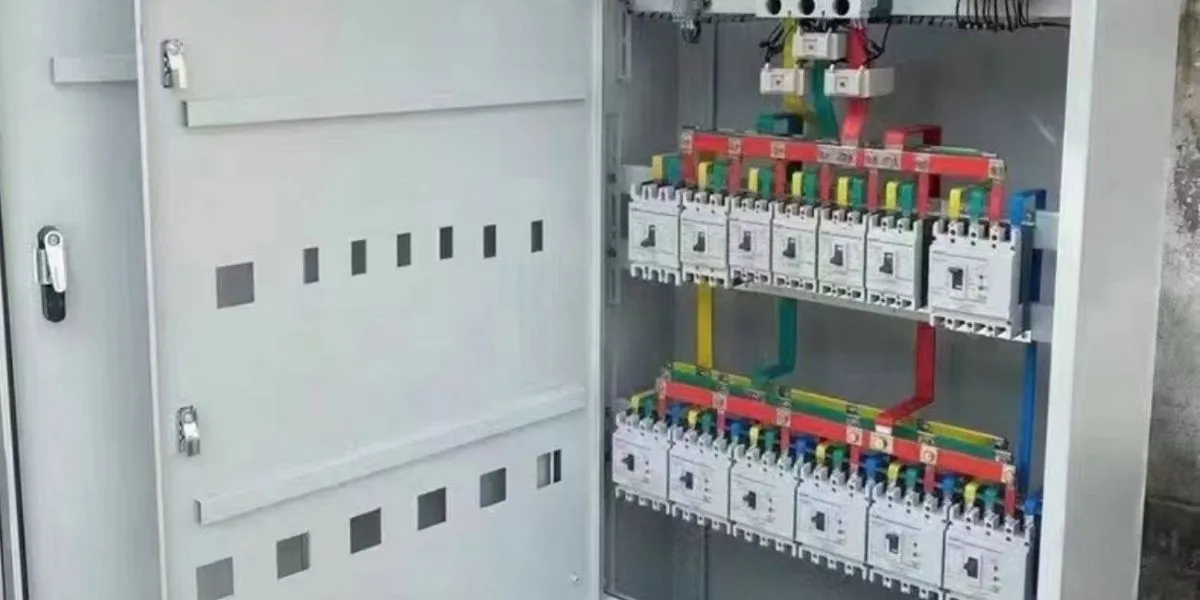

3.2 Workshop Power Distribution Systems

At the workshop level, smart power distribution systems can achieve:

- Real-time monitoring of low-voltage distribution cabinets

- Intelligent control and protection of motors

- Dynamic monitoring and analysis of workshop loads

- Quick fault location and isolation

3.3 New Energy Access and Microgrids

For industrial enterprises connected to new energy sources, smart power distribution systems can achieve:

- Intelligent access to new energy sources such as photovoltaic and wind power

- Optimal scheduling of energy storage systems

- Coordinated control of microgrids

- Smooth switching between grid-connected and off-grid modes

4. Advantages of Smart Power Distribution Systems

4.1 Improved Power Supply Reliability

- Real-time monitoring of equipment status, early detection of potential faults

- Quick fault location and isolation, reducing power outage time

- Realization of self-healing control of power distribution systems

4.2 Enhanced Energy Efficiency Management

- Precise monitoring of energy consumption in each link, identifying energy-saving potential

- Optimized load distribution, reducing losses

- Realization of dynamic adjustment of reactive power compensation

4.3 Enhanced Operational Safety

- Real-time monitoring of electrical parameters, preventing overload, short circuit and other faults

- Realization of remote operation, reducing the risk of on-site operations for personnel

- Establishment of a complete safety early warning mechanism

4.4 Reduced Operation and Maintenance Costs

- Implementation of predictive maintenance, reducing unnecessary inspections

- Remote monitoring and diagnosis, reducing manual inspection costs

- Optimization of equipment operation, extending equipment service life

5. Case Study: Smart Power Distribution System for a Automobile Manufacturing Plant

5.1 Project Background

A large automobile manufacturing plant had problems such as aging equipment, backward monitoring methods, and lack of energy efficiency management in its original power distribution system, and planned to upgrade to a smart power distribution system.

5.2 System Architecture

- Perception Layer: Install smart meters, temperature sensors, humidity sensors, vibration sensors and other equipment

- Network Layer: Adopt industrial Ethernet and wireless communication technologies to realize equipment interconnection

- Platform Layer: Establish a smart power distribution monitoring platform to realize data collection, storage, analysis and visualization

- Application Layer: Provide functions such as equipment monitoring, energy efficiency management, fault diagnosis, and report analysis

5.3 Implementation Effects

- Power supply reliability improved to 99.99%

- Energy utilization rate increased by 15%

- Operation and maintenance costs reduced by 30%

- Fault response time shortened by 80%

6. Future Development Trends of Smart Power Distribution Systems

6.1 Digital Transformation

With the development of digital twin technology, smart power distribution systems will realize real-time mapping between physical devices and digital models, improving the system’s visualization and simulation capabilities.

6.2 Deep Integration with Edge Computing

Edge computing technology will be widely used in smart power distribution systems, realizing local data processing and real-time decision-making, reducing network latency and bandwidth pressure.

6.3 Multi-energy Coordination and Integrated Energy Management

Smart power distribution systems will deeply integrate with heating, gas supply and other systems, realizing coordinated optimization and integrated management of multiple energy sources.

6.4 Standardization and Openness

Future smart power distribution systems will pay more attention to standardization and openness, supporting interconnection and interoperability of equipment from different manufacturers.

7. Conclusion

Smart power distribution systems are an important means for industrial fields to achieve efficient, safe, and reliable power management, with broad application prospects. With the continuous development of IoT, big data, AI and other technologies, smart power distribution systems will develop in a more intelligent, digital, and standardized direction, providing strong support for the digital transformation of industrial enterprises.

8. References

- “Smart Grid Technology Standard System”

- “Industrial Internet of Things White Paper”

- “Smart Power Distribution System Design Specification”

- “Power System Automation” journal