Industrial Low-Voltage Distribution Cabinet Selection Guide and Application Practice

Senkuo Electromechanical

Electrical Technology ExpertFocused on the research and application of industrial electrical automation, smart power distribution systems, and new energy technologies, with rich industrial project experience.

1. Introduction

Low-voltage distribution cabinets are core equipment in industrial power distribution systems, responsible for converting high-voltage electrical energy into low-voltage electrical energy and distributing it to various electrical equipment. Correct selection and use of low-voltage distribution cabinets are crucial to ensuring safe and reliable power supply for industrial enterprises. This article will comprehensively introduce the selection points, technical parameters, installation specifications, and maintenance management of industrial low-voltage distribution cabinets. For high-voltage distribution equipment selection, you can refer to Technical Features and Selection Guide for High Voltage Switchgear; for smart power distribution systems, you can refer to Application and Development of Smart Power Distribution Systems in Industrial Fields.

2. Classification and Structure of Low-Voltage Distribution Cabinets

2.1 Classification of Low-Voltage Distribution Cabinets

According to structural forms and uses, low-voltage distribution cabinets are mainly divided into the following categories:

- Withdrawable Distribution Cabinets: GCK, GCS, MNS, and other series

- Fixed Distribution Cabinets: GGD, XL-21, and other series

- Intelligent Distribution Cabinets: Distribution cabinets equipped with intelligent monitoring systems

- Reactive Power Compensation Cabinets: Used to compensate system reactive power

- Frequency Conversion Control Cabinets: Used to control frequency conversion speed regulation systems

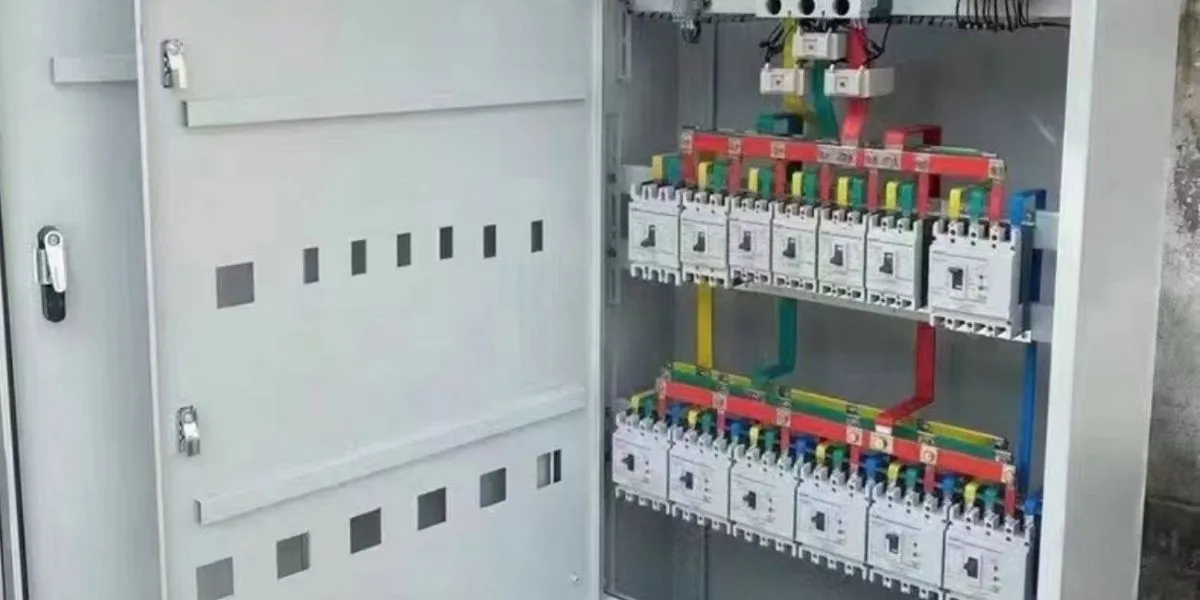

2.2 Basic Structure of Low-Voltage Distribution Cabinets

The basic structure of low-voltage distribution cabinets includes:

- Cabinet body: Made of metal materials, providing protection and support

- Busbar system: Including main busbar, branch busbar, and grounding busbar

- Electrical components: Circuit breakers, contactors, relays, fuses, etc.

- Secondary circuit: Control, protection, and monitoring circuits

- Auxiliary facilities: Ventilation, lighting, grounding, etc.

3. Selection Points for Low-Voltage Distribution Cabinets

3.1 Load Calculation and Capacity Determination

- Accurately calculate electrical loads, including active loads and reactive loads

- Consider the simultaneous coefficient and demand coefficient of loads

- Reserve a certain expansion space (usually 15%-30%)

- Determine the rated current and short-circuit withstand capacity of the main busbar

3.2 Cabinet Form Selection

- Withdrawable vs Fixed: Withdrawable is convenient for maintenance and component replacement but has higher cost; fixed has lower cost but is inconvenient for maintenance

- Protection Level: Select IP30, IP40, IP54, etc., according to the installation environment

- Installation Method: Floor-standing, wall-mounted, embedded, etc.

- Size Specifications: Determine according to site space and number of components

3.3 Electrical Component Selection

3.3.1 Circuit Breaker Selection

- Molded Case Circuit Breaker (MCCB): Used for distribution lines and motor protection

- Air Circuit Breaker (ACB): Used for main incoming lines and large-capacity feeders

- Miniature Circuit Breaker (MCB): Used for terminal distribution lines

- Selection points: Rated current, short-circuit breaking capacity, protection characteristics, operation mode

3.3.2 Contactor Selection

- Select according to load type (motor, resistive load, etc.)

- Rated current should be greater than or equal to 1.2-1.5 times the load current

- Coil voltage should match the control circuit voltage

- Consider operation frequency and service life

3.3.3 Relays and Protection Devices

- Thermal relay: Used for motor overload protection

- Intermediate relay: Used for signal amplification and conversion

- Intelligent protection device: Used for comprehensive motor protection

- Selection points: Protection functions, setting range, communication capabilities

3.4 Busbar System Selection

- Busbar material: Copper busbar or aluminum busbar, copper busbar has good electrical conductivity but high cost

- Busbar cross-section: Select according to rated current and temperature rise requirements

- Busbar connection: Bolt connection or welding connection

- Short-circuit withstand capacity: Should meet system short-circuit current requirements

3.5 Intelligent Monitoring System Selection

- Intelligent electricity meters: Used for energy metering and monitoring

- Temperature sensors: Used for busbar and circuit breaker contact temperature monitoring

- Current/voltage sensors: Used for electrical parameter monitoring

- Communication modules: Support Modbus, Profinet, and other communication protocols

- Monitoring software: Realize remote monitoring and data analysis

4. Installation Specifications for Low-Voltage Distribution Cabinets

4.1 Installation Environment Requirements

- Ambient temperature: -5℃~+40℃, 24-hour average temperature not exceeding +35℃

- Relative humidity: ≤90% (at 25℃)

- Altitude: ≤2000m

- Avoid installation in environments with dust, corrosive gases, and severe vibration

4.2 Pre-installation Preparation

- Check if the cabinet body is intact

- Check if electrical components are complete and intact

- Verify product qualification certificates and technical documents

- Prepare necessary installation tools and materials

4.3 Installation Process

- Cabinet positioning: Ensure levelness and verticality meet requirements

- Busbar connection: Connect busbars according to design requirements, ensure good contact

- Cable laying: Lay cables according to specifications, make good identification

- Secondary circuit wiring: Ensure correct and firm wiring

- Grounding system: Ensure reliable grounding, grounding resistance ≤4Ω

4.4 Inspection and Testing After Installation

- Appearance inspection: Check installation quality and wiring conditions

- Insulation resistance testing: Insulation resistance of each circuit should be ≥1MΩ

- Withstand voltage testing: Conduct withstand voltage testing according to specifications

- Function testing: Test the action performance of circuit breakers, contactors, and other components

- Simulation testing: Simulate various fault conditions, test protection functions

5. Maintenance Management of Low-Voltage Distribution Cabinets

5.1 Daily Maintenance

- Regularly check the appearance and protection of the cabinet body

- Check the operating status and temperature of electrical components

- Check if busbar connection parts are loose or overheated

- Check if secondary circuit wiring is firm

- Clean dust and debris inside the cabinet body

5.2 Regular Maintenance

- Monthly maintenance: Check the operating status of main electrical components, test protection functions

- Quarterly maintenance: Check busbar connection parts, tighten loose bolts

- Annual maintenance: Conduct comprehensive inspection and testing, replace aging components

- Overhaul: Conduct overhaul every 3-5 years, including replacement of main electrical components and busbars

5.3 Common Fault Handling

- Circuit breaker tripping: Check short-circuit, overload, and other fault causes, reclose after elimination

- Component overheating: Check poor contact, overload, and other causes, handle in time

- Secondary circuit fault: Check wiring, relays, and other components, eliminate faults

- Communication fault: Check communication modules and lines, reconfigure communication parameters

6. Application Cases of Low-Voltage Distribution Cabinets

6.1 Low-Voltage Distribution System of a Machinery Processing Plant

Project Overview

- Production workshops: 3, total electrical load: 2000kW

- Low-voltage distribution cabinet type: GCS withdrawable distribution cabinet

- Main incoming circuit breaker: Air circuit breaker, rated current 4000A

- Feeder circuits: 50, using molded case circuit breakers

- Intelligent monitoring: Equipped with intelligent electricity meters and temperature sensors, realizing remote monitoring

Operation Effect

- Power supply reliability: 99.98%

- Maintenance cost: Reduced by 35%

- Fault response time: Shortened by 70%

- Energy management: Realized refined management of electrical energy

6.2 Low-Voltage Distribution System Transformation of a Chemical Enterprise

Project Background

- Original distribution cabinets: GGD fixed distribution cabinets, service life over 15 years

- Existing problems: Equipment aging, imperfect protection functions, no monitoring system

Transformation Plan

- Replaced with GCK withdrawable distribution cabinets

- Equipped with intelligent protection devices and monitoring systems

- Optimized busbar system, improved short-circuit withstand capacity

- Added reactive power compensation devices, improved power factor

Transformation Effect

- Power supply reliability significantly improved

- Energy utilization rate increased by 12%

- Maintenance workload reduced by 50%

- Realized predictive maintenance

7. Development Trends of Low-Voltage Distribution Cabinets

7.1 Intelligentization

- Wide application of intelligent components

- Deep integration of Internet of Things technology

- Big data analysis and predictive maintenance

- Remote monitoring and operation

7.2 Modularization

- Modular design, convenient for expansion and maintenance

- Standardized components, improving interchangeability

- Quick assembly, shortening installation cycle

7.3 Green Environmental Protection

- Use of environmentally friendly materials, reducing environmental pollution

- Improving energy efficiency, reducing energy consumption

- Recyclable design, reducing resource waste

7.4 Safety Improvement

- Perfect protection functions

- Misoperation prevention design

- Arc fault detection and protection

- Insulation monitoring and early warning

8. Conclusion

Low-voltage distribution cabinets are key equipment in industrial power distribution systems, and correct selection, installation, and maintenance are crucial to ensuring safe and reliable power supply for industrial enterprises. With the continuous development of intelligent, modular, green environmental protection and other technologies, low-voltage distribution cabinets will develop in a more intelligent, efficient, safe, and reliable direction. Industrial electrical engineers should constantly learn and master new technologies, improve the selection and use level of low-voltage distribution cabinets, and provide strong power support for the development of industrial enterprises.

9. References

- “Low-Voltage Switchgear and Controlgear Part 1: General Rules” (GB 7251.1)

- “Design Code for Low-Voltage Distribution Cabinets” (GB 50054)

- “Industrial and Civil Power Supply and Distribution Design Manual”

- “Low-Voltage Electrical Equipment Selection Manual”