Application and Optimization of Photovoltaic Power Generation Technology in Industrial Field

Senkuo Electromechanical

Electrical Technology ExpertFocused on the research and application of industrial electrical automation, smart power distribution systems, and new energy technologies, with rich industrial project experience.

1. Introduction

With the increasingly serious global energy crisis and environmental problems, industrial enterprises are facing enormous pressure to save energy and reduce emissions. As a clean and renewable energy form, photovoltaic power generation is gradually becoming an important choice for industrial enterprises to achieve green energy transformation. This article will deeply discuss the application status, system design points, economic benefit analysis, and future development trends of photovoltaic power generation technology in the industrial field.

2. Basic Principles and Development Status of Photovoltaic Power Generation Technology

2.1 Basic Principles of Photovoltaic Power Generation

Photovoltaic power generation is a technology that directly converts solar energy into electrical energy using the photovoltaic effect of semiconductor materials. Its basic principle is: when sunlight irradiates on photovoltaic cells, photons interact with electrons in semiconductor materials, causing electrons to gain enough energy to escape from atoms, forming free electrons and holes, thereby generating electromotive force.

2.2 Development Status of Photovoltaic Power Generation Technology

In recent years, photovoltaic power generation technology has developed rapidly, mainly manifested in:

- Continuous improvement of photovoltaic cell conversion efficiency, with monocrystalline silicon cell efficiency exceeding 26%

- Continuous decline in component costs, dropping by more than 90% in the past 10 years

- Increasingly mature system integration technology, with continuous improvement of power generation efficiency

- Rapid development of energy storage technology, solving the intermittency problem of photovoltaic power generation

3. Design Points of Photovoltaic Power Generation Systems in Industrial Field

3.1 Site Selection and Site Evaluation

When constructing photovoltaic power generation systems, industrial enterprises need to consider the following factors:

- Roof area and load-bearing capacity

- Solar resource conditions

- Grid connection conditions

- Surrounding environmental impact

3.2 System Capacity Design

System capacity design needs to consider:

- Enterprise electricity load characteristics

- Available roof area

- Local solar conditions

- Investment budget and payback period

3.3 Component Selection

Component selection needs to consider:

- Photovoltaic cell type (monocrystalline silicon, polycrystalline silicon, thin film)

- Component efficiency and lifespan

- Mechanical properties such as wind resistance and snow resistance

- Temperature coefficient and low-light performance

3.4 Inverter Selection

Inverter selection needs to consider:

- Inverter type (centralized, string, micro-inverter)

- Conversion efficiency

- Reliability and lifespan

- Grid connection performance and power quality

3.5 System Integration and Installation

System integration and installation need to consider:

- Component arrangement and tilt angle design

- Bracket system selection

- Cable routing and protection

- Grounding and lightning protection design

4. Application Cases of Photovoltaic Power Generation Systems in Industrial Field

4.1 Roof Photovoltaic Power Generation Project of an Electronic Factory

Project Overview

- Installed capacity: 5MWp

- Component type: Monocrystalline silicon components

- Inverter type: String inverter

- Annual power generation: About 5.5 million kWh

- Floor area: About 45,000 square meters

Implementation Effect

- Annual electricity cost saving: About 3.85 million yuan

- Annual carbon dioxide emission reduction: About 4,400 tons

- Investment payback period: About 5.5 years

- Equipment utilization rate: About 98%

4.2 Distributed Photovoltaic Power Generation Project of an Automotive Parts Manufacturer

Project Overview

- Installed capacity: 2MWp

- Component type: High-efficiency monocrystalline silicon components

- Inverter type: Centralized inverter

- Annual power generation: About 2.2 million kWh

- Floor area: About 18,000 square meters

Implementation Effect

- Annual electricity cost saving: About 1.54 million yuan

- Annual carbon dioxide emission reduction: About 1,760 tons

- Investment payback period: About 6 years

- Self-consumption rate: About 95%

5. Economic Benefit Analysis of Industrial Photovoltaic Power Generation Systems

5.1 Investment Cost Composition

The investment cost of industrial photovoltaic power generation systems mainly includes:

- Photovoltaic component cost (about 50%)

- Inverter cost (about 15%)

- Bracket and installation cost (about 15%)

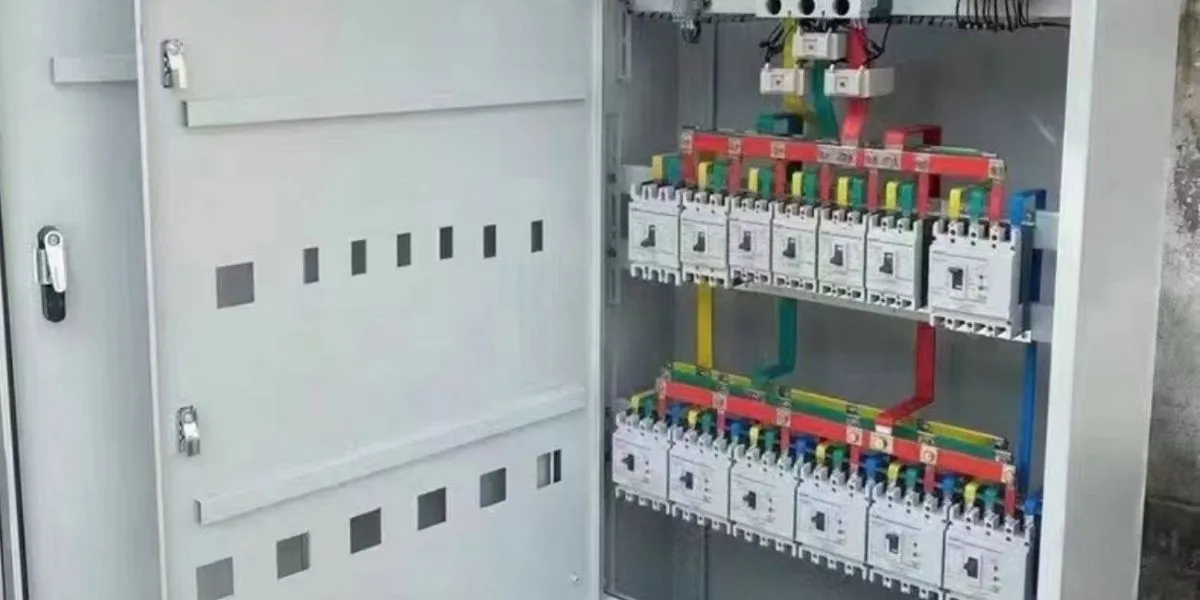

- Cable and electrical equipment cost (about 10%)

- Design, commissioning, and operation and maintenance cost (about 10%)

5.2 Revenue Sources

The revenue of industrial photovoltaic power generation systems mainly includes:

- Saved electricity expenses

- National and local subsidy policies

- Carbon trading revenue

- Peak-valley electricity price difference revenue

5.3 Investment Return Analysis

Investment return analysis needs to consider:

- Initial investment cost

- Annual power generation and revenue

- Operation and maintenance costs

- Inflation rate

- Discount rate

6. Optimization Strategies for Industrial Photovoltaic Power Generation Systems

6.1 Improving System Power Generation Efficiency

- Select high-efficiency photovoltaic components

- Optimize component arrangement and tilt angle

- Adopt tracking systems

- Strengthen component cleaning and maintenance

6.2 Improving Self-consumption Rate

- Combine with enterprise electricity load characteristics to optimize system design

- Configure energy storage systems to achieve peak-valley regulation

- Adopt intelligent control systems to optimize energy dispatching

6.3 Reducing Operation and Maintenance Costs

- Adopt intelligent operation and maintenance management systems

- Implement remote monitoring and diagnosis

- Establish predictive maintenance mechanisms

6.4 Improving System Reliability

- Select high-reliability equipment

- Optimize system design to improve redundancy

- Strengthen lightning protection, bird prevention, and pollution prevention measures

7. Future Development Trends of Industrial Photovoltaic Power Generation

7.1 Technology Development Trends

- Further improvement of photovoltaic cell efficiency

- Wide application of bifacial power generation technology

- Commercialization of new battery technologies such as perovskite

- Deep integration of photovoltaics and energy storage

7.2 Application Model Innovation

- Building-integrated photovoltaics (BIPV)

- Photovoltaic + energy storage + microgrid mode

- Virtual power plant technology application

- Green power trading mechanism

7.3 Policy and Market Environment

- Promotion of carbon peak and carbon neutrality policies

- Improvement of green manufacturing standard system

- Deepening of power market reform

- Market-oriented trading of distributed energy

8. Conclusion

Photovoltaic power generation technology has broad application prospects in the industrial field, which can not only help industrial enterprises reduce energy costs but also reduce carbon emissions and achieve green manufacturing. With the continuous advancement of technology and policy support, photovoltaic power generation will play an increasingly important role in the industrial field. Industrial enterprises should reasonably plan and design photovoltaic power generation systems according to their actual conditions, optimize operation management, and improve economic and environmental benefits.

9. References

- “Photovoltaic Power Generation System Design Specifications”

- “Interim Measures for the Management of Distributed Photovoltaic Power Generation Projects”

- “Industrial Energy Conservation Diagnosis Service Action Plan”

- “14th Five-Year Plan for Solar Photovoltaic Industry Development”