Technical Features and Selection Guide for High Voltage Switchgear

Engineer Wang

High Voltage Electrical ExpertGraduated from North China Electric Power University with a major in Electrical Engineering, with 15 years of experience in design and operation of high-voltage power distribution systems. Participated in the electrical system design and commissioning work of multiple large industrial projects.

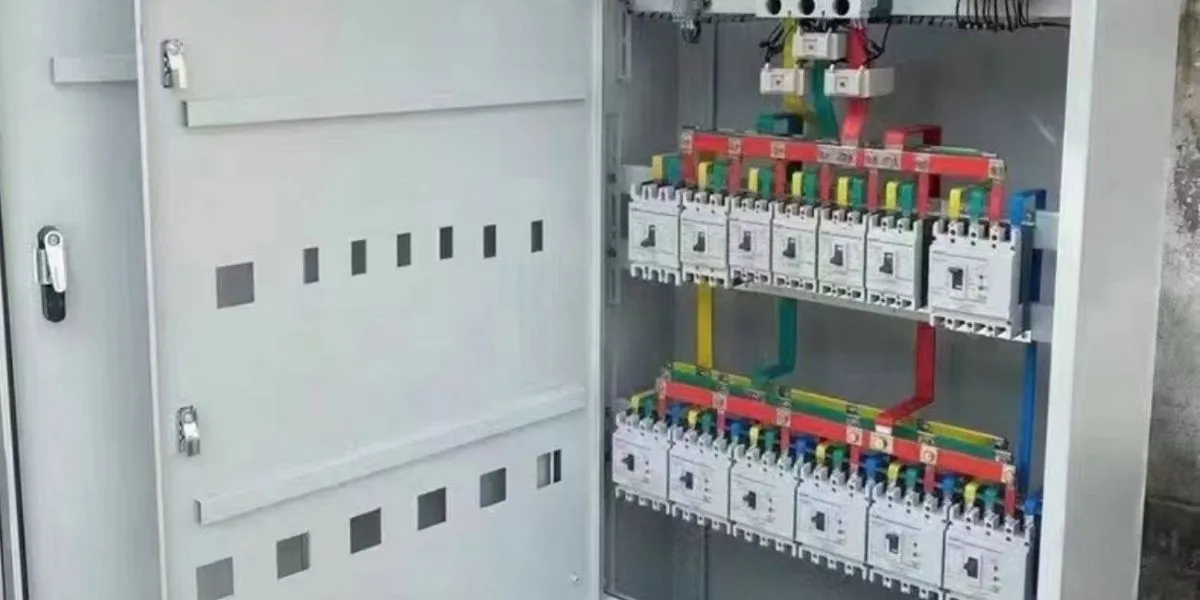

High voltage switchgear is an indispensable important equipment in power systems, mainly used for switching, controlling, or protecting in power generation, transmission, distribution, energy conversion, and consumption. With the development of the power industry, the technology of high voltage switchgear is also constantly progressing, and its safety, reliability, and intelligence level have been significantly improved, becoming an important part of smart power distribution systems. For detailed information on smart power distribution systems, you can refer to Application and Advantages of Smart Power Distribution Systems in Modern Factories.

1. Core Technical Features of High Voltage Switchgear

Modern high voltage switchgear integrates a variety of advanced technologies, mainly with the following characteristics:

- Modular Design: Adopts standardized modules, easy for installation, maintenance, and expansion, shortening fault handling time.

- Excellent Insulation Performance: Uses SF6 gas, vacuum, or solid insulation materials, improving the insulation strength and safety of the equipment.

- Intelligent Monitoring: Built-in sensors and intelligent modules, real-time monitoring of equipment status, realizing remote monitoring and early warning.

- High Breaking Capacity: Can reliably break short-circuit current, protecting the safe operation of power systems.

- Strong Environmental Adaptability: Can work stably in harsh environments such as high temperature, high humidity, and dusty conditions.

2. Main Types and Application Scenarios of High Voltage Switchgear

According to different classification standards, high voltage switchgear can be divided into multiple types, suitable for different application scenarios:

| Type | Features | Application Scenarios |

|---|---|---|

| Armored Removable Switchgear | High safety, convenient maintenance | Power plants, substations |

| Interval Switchgear | Compact structure, high cost performance | Industrial enterprise distribution |

| Box-type Fixed Switchgear | Simple structure, low cost | Rural power grid, small factories |

| SF6 Gas Insulated Switchgear | Small size, excellent insulation performance | Urban distribution network, subway |

3. Key Points for High Voltage Switchgear Selection

Selecting suitable high voltage switchgear requires considering multiple factors to ensure it meets actual engineering needs:

1. Rated Parameter Matching

Select the appropriate product model according to system voltage level, rated current, short-circuit breaking current, and other parameters. Special attention should be paid to the fact that the short-circuit breaking capacity must be greater than the maximum short-circuit current that may occur in the system.

2. Environmental Adaptability

Consider the environmental conditions of the installation site, such as temperature, humidity, altitude, dust, etc. For special environments, products with corresponding protection levels and special treatments should be selected.

3. Operation Mode Selection

Select the appropriate operation mode according to operation and maintenance requirements, including manual operation, electric operation, remote control, etc. For unattended substations, intelligent switchgear with remote monitoring and operation functions should be selected.

4. Cabinet Material Selection

The main cabinet materials include cold-rolled steel plates, stainless steel, etc. Cold-rolled steel plates can be used in ordinary environments, while stainless steel materials should be used in corrosive environments, and attention should be paid to surface treatment processes.

5. Intelligence Level

According to system intelligence requirements, select switchgear with condition monitoring, data acquisition, and communication functions. Intelligent switchgear can realize condition-based maintenance, improve power supply reliability, and reduce operation and maintenance costs.

4. Installation and Maintenance Notes

Correct installation and maintenance are the keys to ensuring the safe and reliable operation of high voltage switchgear:

Notes

- Before installation, check whether the equipment is intact, whether accessories are complete, and whether technical documents are complete.

- During installation, strictly follow the installation instructions to ensure that all parameters meet the requirements.

- Regular maintenance checks, including cleaning, tightening, insulation testing, operating mechanism inspection, etc.

- For SF6 gas insulated switchgear, regularly detect gas pressure and purity to prevent leakage.

- Maintenance personnel must undergo professional training and strictly follow safety operation procedures.

5. Conclusion

The selection of high voltage switchgear is an important link in power system design, directly related to the safe and reliable operation of power systems. In the selection process, factors such as system requirements, environmental conditions, operation and maintenance should be comprehensively considered to select technologically advanced, reliable, and economically applicable products.

With the development of intelligent technology, high voltage switchgear is developing in the direction of miniaturization, intelligence, and green environmental protection. Choosing switchgear products with advanced technology can not only meet current needs but also adapt to future development trends of power systems, providing reliable guarantees for the safe and stable operation of power systems.